Berliners and donuts of the highest quality

– in craft bakeries and

semi-industrial production facilities

Producing Berliners and donuts

What does the perfect Berliner and donut taste like?

There are no limits to creativity when it comes to the taste and visual design of Berliners and donuts. Exotic fillings, alternative doughs (vegan or gluten-free) and unusual toppings are all the rage. Despite countless variations, one demand is always the same: best taste with low fat content.

Find the right machine for your production size

Our deep frying equipment provides you with optimum assistance in the production of delicious Berliners, donuts, etc. In our various series you will easily find the right machine for your requirements and production size. Many machines can be equipped with useful components that make your everyday life easier.

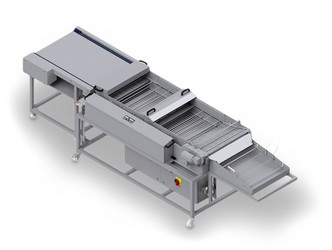

Deep fryer

Deep fryer with automatic turns

DLA 150

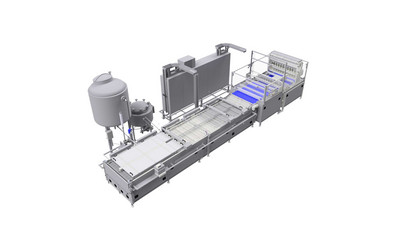

Continuous fryer for donuts

with automatic filling station

Trio station of the Linie 2000 Energy with filling and sugar turntable

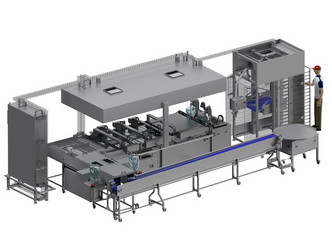

Industrial continuous deep fryer

Industrial continuous deep fryer

RIEHLE quality

We have years of experience in working with bakeries, especially in the field of deep frying. Over the years, we have equipped our machines with various technologies, but we only kept the ones that have proven to be beneficial. Nowadays, we regularly update our equipment with the latest technology for increased comfort and massively reduced workload.

Our sales staff will be happy to answer your questions about our solutions for ‘Berliner’ donuts and regular donuts.

![Automatic deep fryer L2000 A [Translate to Englisch:]](/fileadmin/_processed_/2/4/csm_WP-Riehle-Linie2000A_2_65dfb4021b.png)

![DLA Industry Touch [Translate to Englisch:]](/fileadmin/_processed_/8/1/csm_WP-Riehle_DLA_industry-touch_74c2867c9a.jpg)