Fried products

Linie 2000A

![Automatic deep fryer L2000 A [Translate to Englisch:]](/fileadmin/wpriehle/produktwelt/Linie-2000A/WP-Riehle-Linie2000A_2.png)

- Automatic turning

- Automatic termination of the baking process

- Operator-independent product quality

The automated open kettle fryer

for the highest of demands

With the Linie 2000A and Vario station, fully automatic baking is possible thanks to programmable baking processes and automatic turning. The volume steam lid remains closed until the first turn, thus ensuring larger volume of baked goods with the same raw weight. The baking process is automatically terminated when the turning basket is moved out. This ensures product quality even if something comes up in between.

Performance, maximum benefit and modular options

Many equipment options that make your daily work easier and increase the quality of your products.

- Handling:

- manual and automatic operation possible

- Baking process:

- automatic turning in the fat for constant dough temperature and less fat absorption

- automatic removal from oil at the end of baking time for consistent baking results

- Fat life:

- Fat monitoring unit for monitoring running time of the deep fry fat

Per baking process

36-120 pcs.

Options

- Proofing chamber with integrated water tank

- Proofing tray (4 and 6 rows)

- High trolleys (16, 18, 20 shelves)

- Sugar tray with hinged angle plate

- available as Vario-Station, two units connected with a joint centre table

- mobile grease cleaner

- Exhaust hood

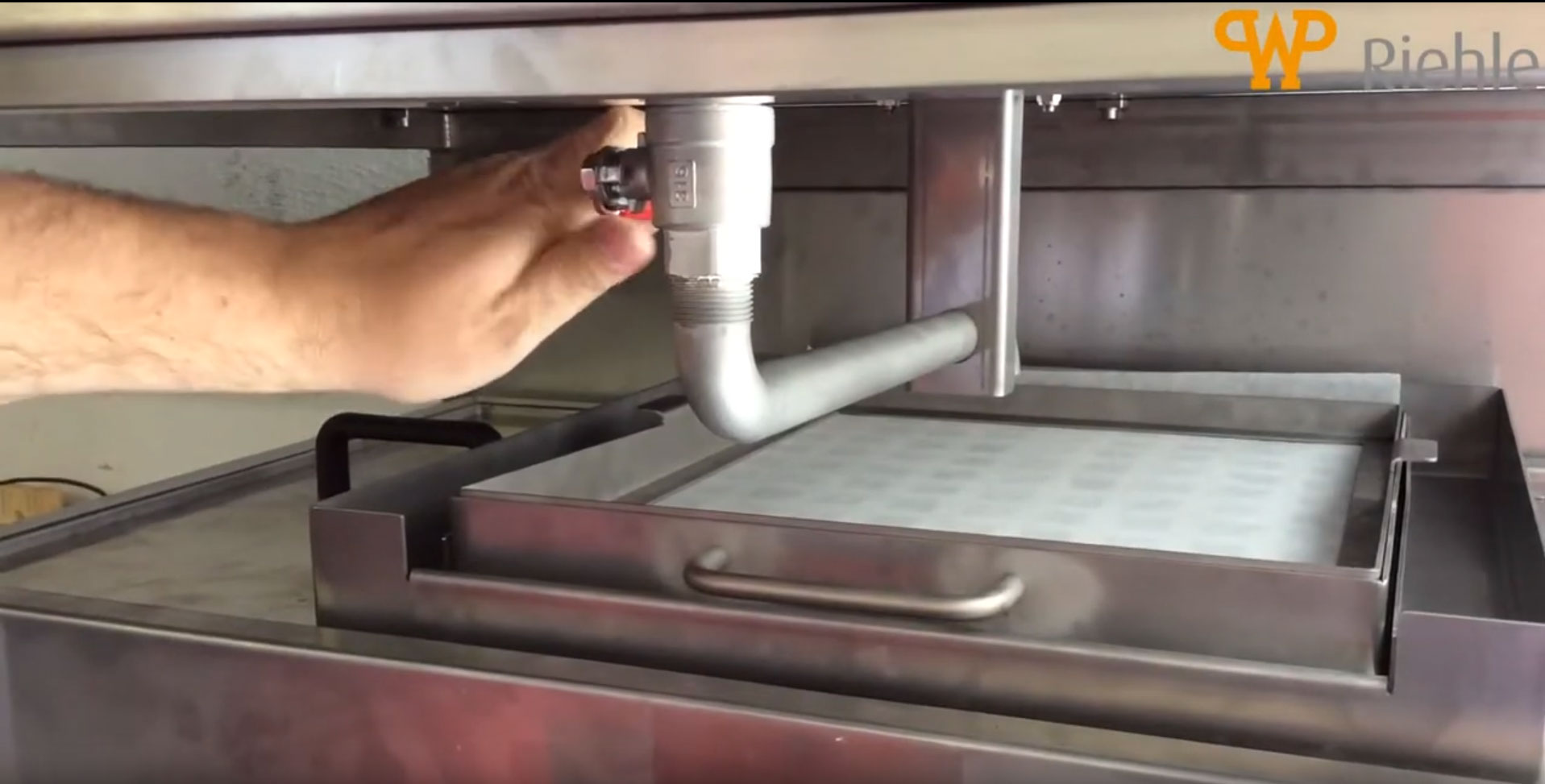

- Oil drain filter tank with backwash pump

For all types of donuts

The automated processes ensure simpler production and consistent product quality. The touch panel control enables intuitive operation.

Cake Donuts

Floating frying of Berliner donuts, donuts and cottage cheese balls

Comprehensive fat maintenance for consistent quality with the tank & pump option

Double the number of dough pieces with the Vario station

Our sales staff will be happy to answer any questions you may have about the product.