Optimise processes and increase efficiency

in the FOOD sector with systems from WP RIEHLE

WP Lebensmitteltechnik RIEHLE GmbH offers innovative solutions for baking, deep-frying, freezing, cooking, and handling products, trays, crates, sacks, and much more. Solutions to make processes future-proof and produce the highest quantities with a consistent level of quality.

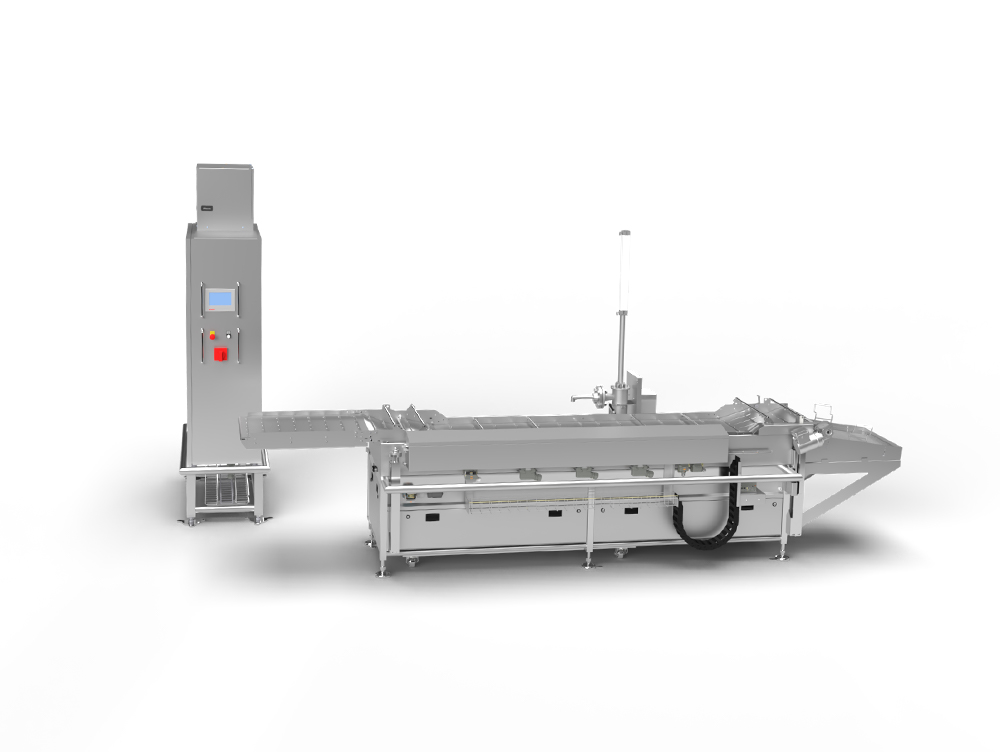

Belt frying with the DLA (SC) continuous fryer

A top seller for 20 years: our DLA (SC). With the continuous deep fryer from WP RIEHLE, you can fry your products with the lowest possible fat absorption. A cycled, direct heating system keeps the temperature constant, with only minimal temperature fluctuations in the fat, which significantly reduces fat absorption and makes your products more digestible. The taste of the product is preserved. With submerged frying, you can also reduce the frying time by up to 40%. The DLA SC is available in various widths (150, 300 and 600) and lengths. The Industry Touch comes with an external control cabinet. The system is perfect for integration into production lines: upstream and downstream machines are possible.

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

With the DLA Industry Touch

Continuous systems for cooking products

You can also use the DLA and DLA SC for cooking: fill them with water or broth and you can cook dumplings, Maultaschen, ravioli, mezzelune, Schlutzkrapfen and much more on a continuous system.

(This continuous system is also available without an infeed table: check out DLA.)

Continuous infrared oven ITES

Thanks to infrared technology, you can achieve the best baking results with up to 70% shorter baking times. Baking takes place from the inside out. The infrared waves penetrate the product and heat the core, while the temperature in the baking chamber heats the product from the outside, thus accelerating the baking process. Due to the low water loss during baking, the products stay fresh longer. Perfect for convenience stores, retail shops, branches and the catering industry.

Baking in record time

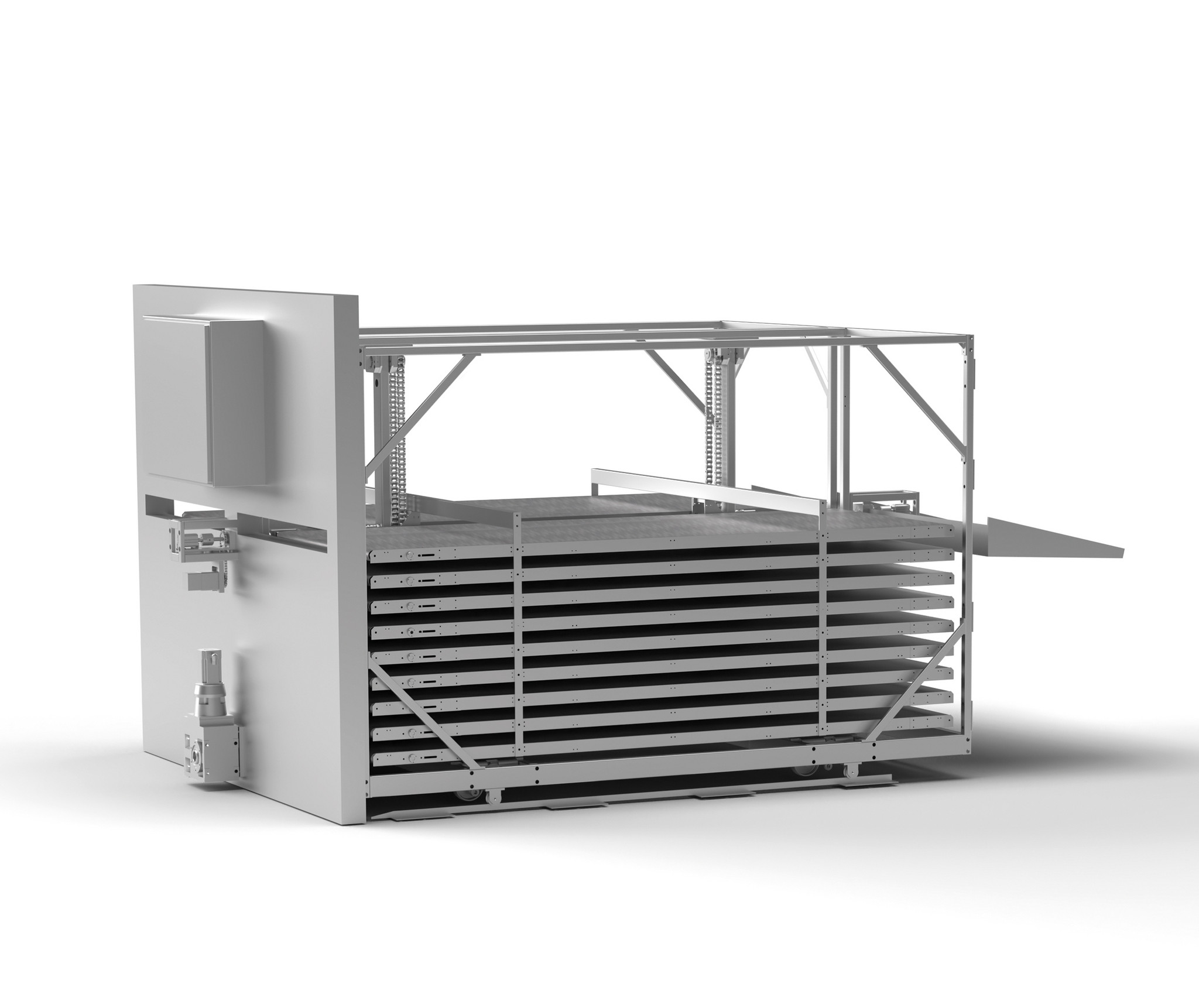

Eco-Froster

Our continuous freezer is particularly suitable for integration into production lines. Its special design is extremely space-saving. The products are frozen on several levels inside the freezer. The products to be frozen are fed into the freezer via a conveyor belt, where they automatically undergo the freezing process and are then discharged at the end according to the first-in-first-out principle. This means that the frozen products can be processed immediately or prepared for shipping.

The hard facts:

- Lower power consumption, as only the products to be frozen need to be cooled. The entire mechanism is permanently located in the cold room.

- Less space required, as the freezer is very compact thanks to its paternoster design. The freezer area is more than four times the size of the freezer's floor space (depending on the model).

- Fully automated processes are possible. The products can be fed in fully automatically, go through the freezing process and then continue on their way at the end.

- Consistent quality and synchronised processes included

- Shock freezing possible

Shock freezing of Pretzels in production line

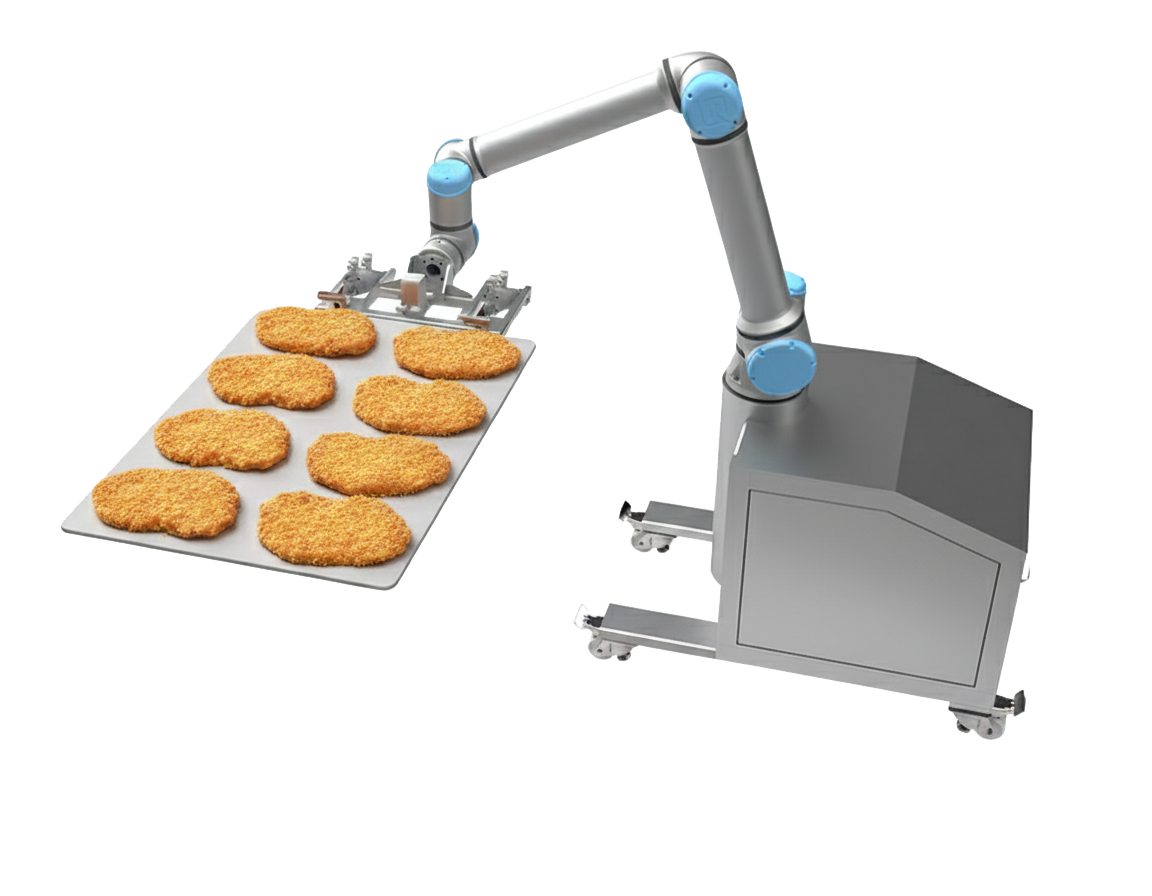

Automation & Robotics

Whether simple automation or robot support: WP RIEHLE offers suitable solutions for almost all automation requirements. Our WP Co-Worker is a very popular colleague. The cobot loads, transports, empties and stacks. Because even in the kitchen, not everything is always creative: the WP Co-Worker takes on simple, monotonous and ergonomically demanding tasks. It supports smooth operations and frees up time for other employees. They are flexible, mobile and do not require any complex safety precautions.

Mobile cobot unloads a lye application machine

Robot support in shipping

Our sales representative will gladly answer your questions about our continuous open kettle fryer.