Robot support in shipping

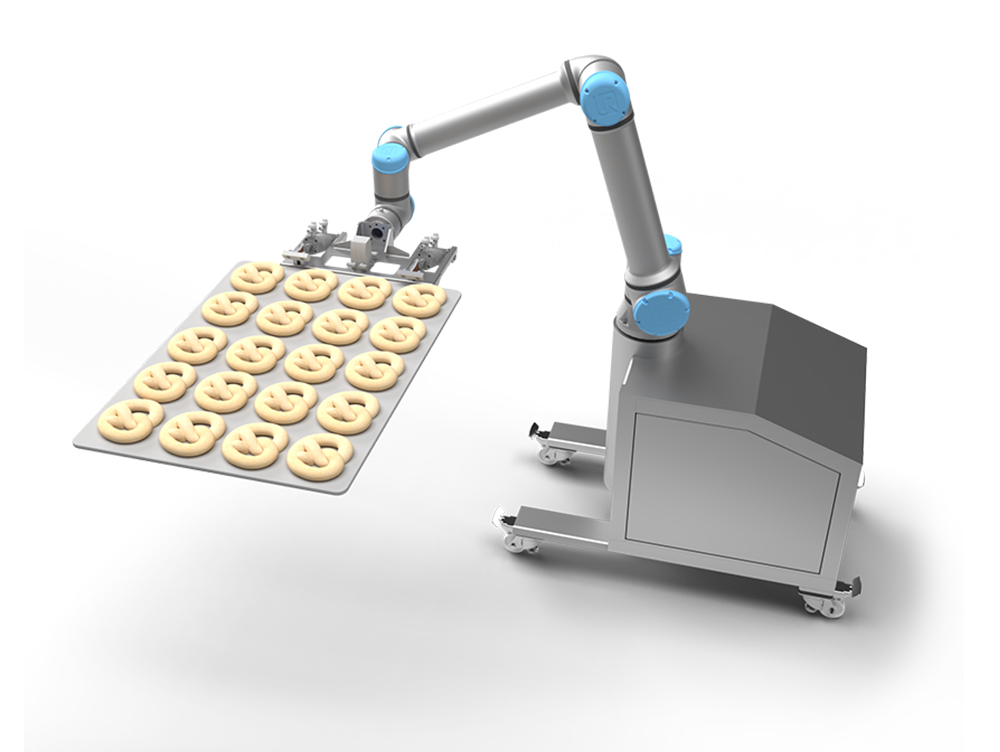

Unloading trays with the WP Co-Worker

WP RIEHLE offers highly versatile robot solutions. Depending on the area of application, various designs, sizes and attachments are available. Here, for example, the WP Co-Worker is used in the shipping department of a medium-sized bakery.

Automated unloading of proofing chamber and rack trolleys – efficient, precise, consistent

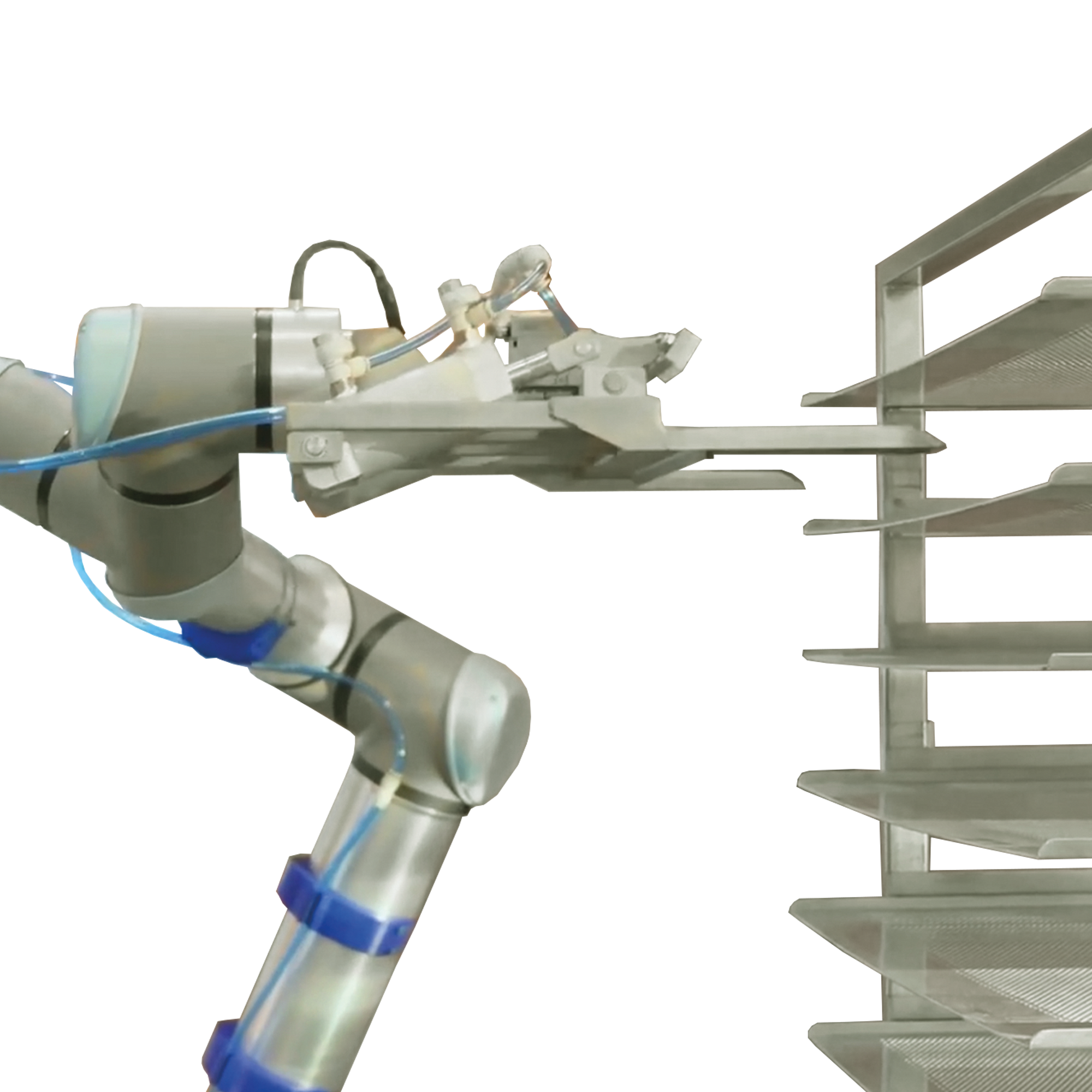

As demonstrated in the video, the robot has been specifically programmed for the automated unloading of proofing chamber and rack trolleys. It systematically removes each tray one by one, positions it precisely in front of a tray chute and tips the products out in a controlled manner. The products slide down the chute directly into the designated product basket, ready for dispatch. This creates a continuous and efficient material flow.

After unloading, each tray is placed in a defined storage position. The robot then starts the same process with the next tray until the entire trolley has been completely processed.

Once the left side of the trolley has been completely unloaded, the robot automatically switches to the right side and continues the unloading process. At the same time, the operating personnel can already position a new trolley on the left side. Once the right side has also been completed, the trolley is changed there as well – while the robot continues to work on the opposite side.

Why you should automate your processes:

- Uniform work rhythm

- Constant workflows without breaks

- Relief for staff by taking over monotonous and physically demanding tasks

- Compensation for staff shortages

- Sustainable reduction in operating costs through staff savings

- Short amortisation period (refinancing period between 12 and 24 months)

Models / Configurations:

- The WP Co-Worker is available with different load capacities and ranges, arm lengths and weights.

- Depending on the area of application, it can have a mobile base (with castors) or be permanently installed.

- Various attachments are available: various grippers and suction attachments.

- Collaborative workflows are possible.

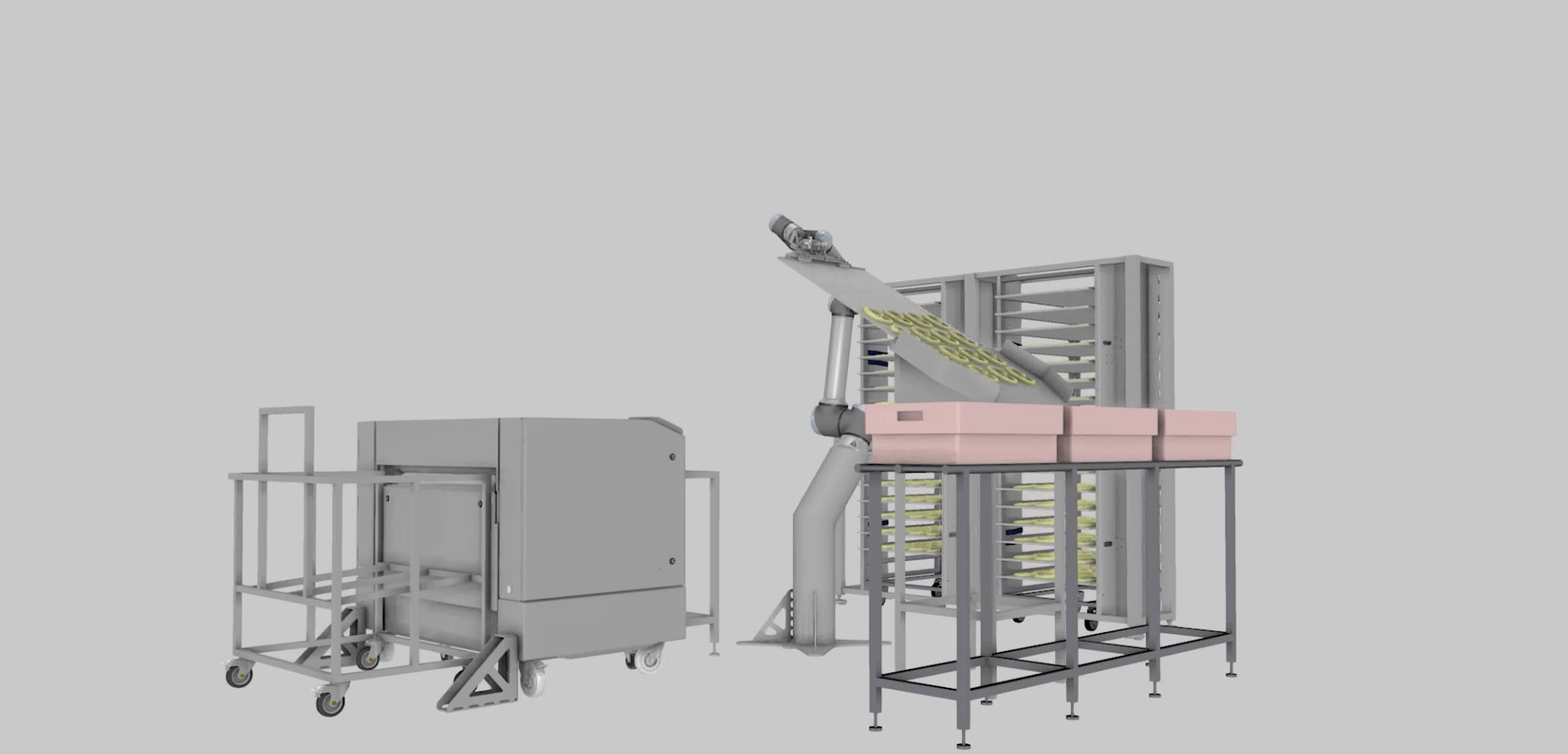

Automated provision of shipping boxes – efficiency right down to the last step

The provision of shipping boxes for the products can be fully automated via a conveyor belt. Empty boxes are transported directly to the filling station, where they are filled with products and then forwarded directly – for example, for loading in the shipping area.

We would be happy to integrate this system for you when planning your new shipping department. This will enable you to create optimal workflows and increase the efficiency of your logistics processes in the long term.

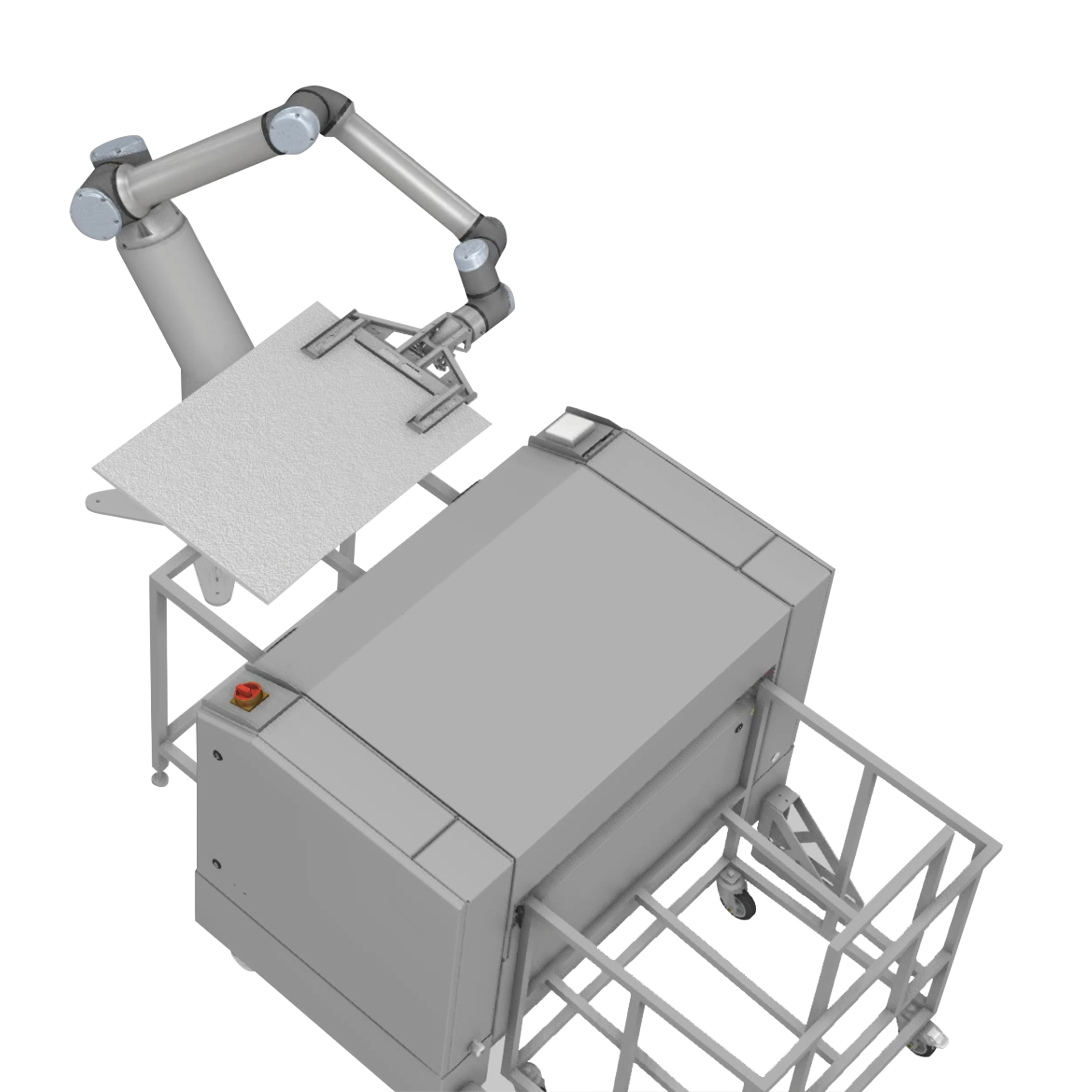

Subsequent automated tray cleaning

The WP Co-Worker robot can be flexibly programmed to place trays in specific positions after unloading. It can also feed trays directly to a cleaning station and start the cleaning process independently – fully automatically and reliably.

Our specially developed cleaning systems are ideal for this step:

BRM – Tray cleaning machine for thorough dry cleaning

BWM – Tray washing machine for intensive wet cleaning

Seamless integration into the overall process not only ensures product quality, but also significantly increases production efficiency.

Dry cleaning