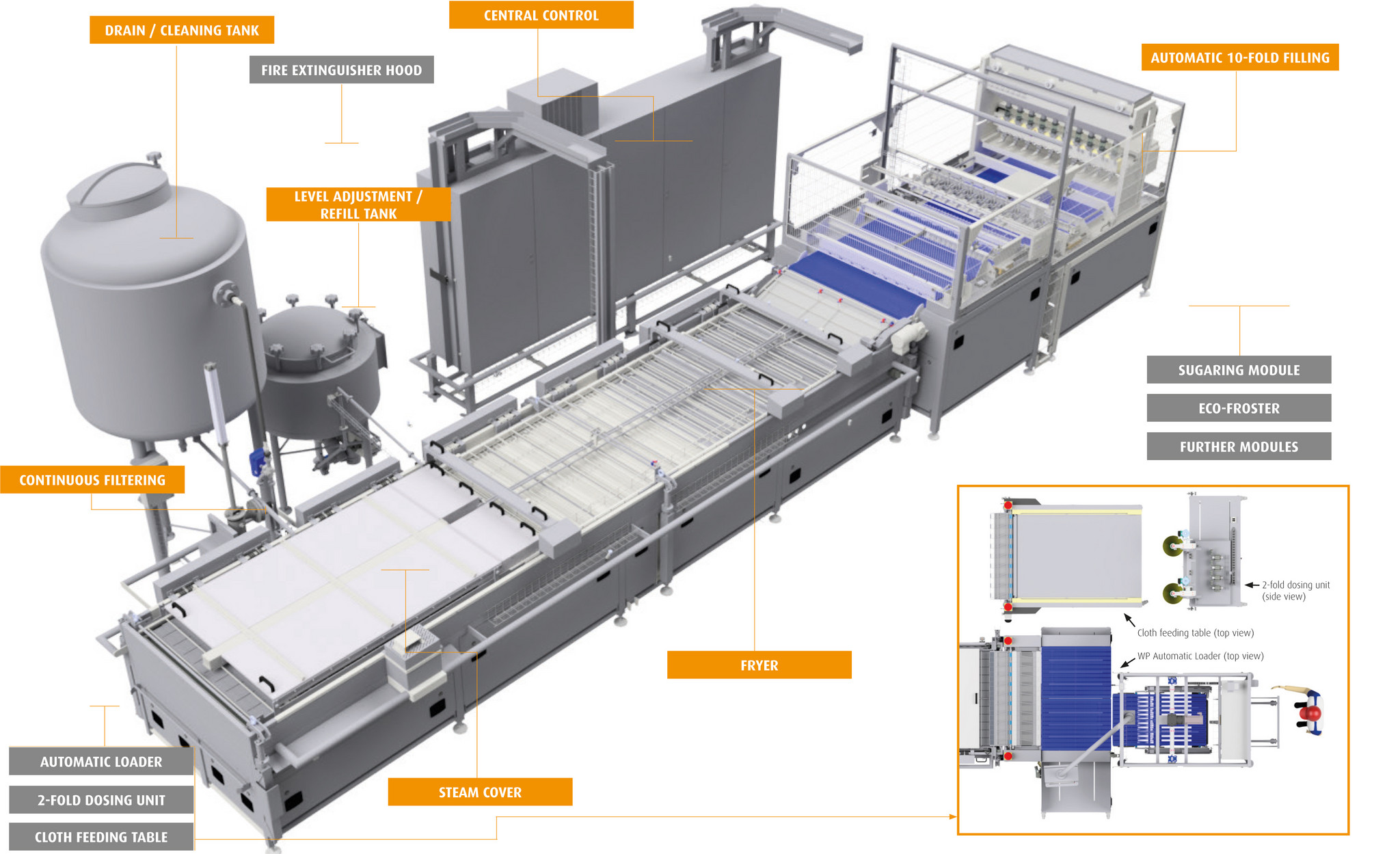

IDA 1100-40

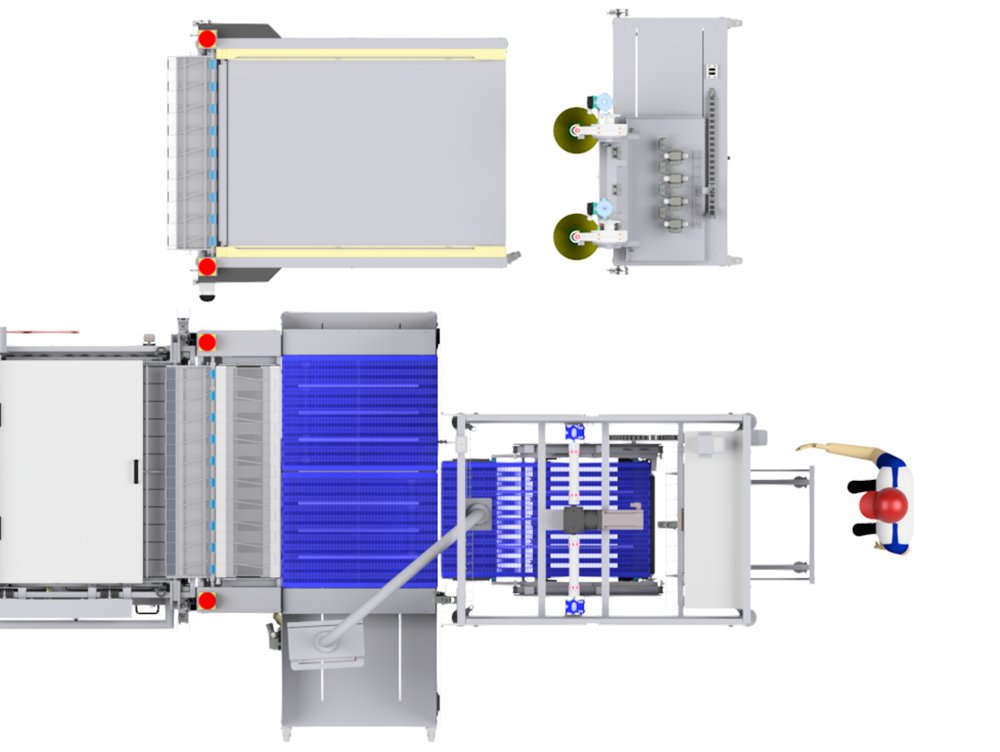

Input systems

Depending on the products, modular input systems for IDA are available:

Cloth feeding table (if necessary with row doubling), automatic loader, system trolleys with transfer / distribution unit, automatic 2-fold dosing for curd cheese dumplings, crullers, cake-donuts, and much more.

Intuitive touch control

- Resistant to grease and dirt

- All connected additional devices are controlled via the baking programmes

- Turning process controlled by servomotors

- Can be networked with LAN or WLAN

- Your machine can be maintained remotely, minimising downtime and costs a technician on-site is not always needed

- Technical support can be provided remotely, so experts can access and assist with real-time troubleshooting and resolution via the internet to support your company technician

- Important data and information of your machine can be accessed remotely, allowing you to monitor the status of your machine and the production data anywhere, anytime

- Touch control panel provides detailed production statistics and reports that offer insights into performance metrics, efficiency and utilisation

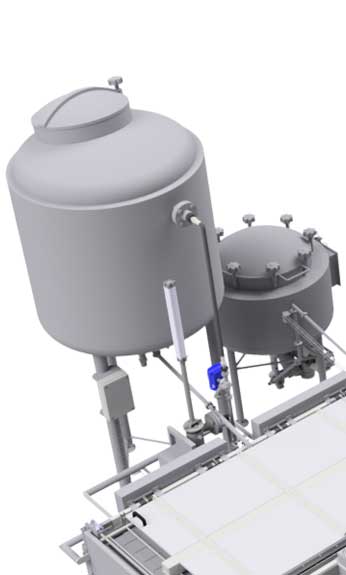

Fat / oil management system

- Automatic level control via heated refill tank

- Heated drain / cleaning tank

- Continuous fat / oil filtration with stainless steel permanent filter element

- Control and programming of all connected system components

Decoration

10-fold filling of Berliners (laterally) and donuts (from above), sugaring, powdering, return conveyor, sugar turntable,

transfer belts to freezers, bouncing belts for tray storage, robot automation

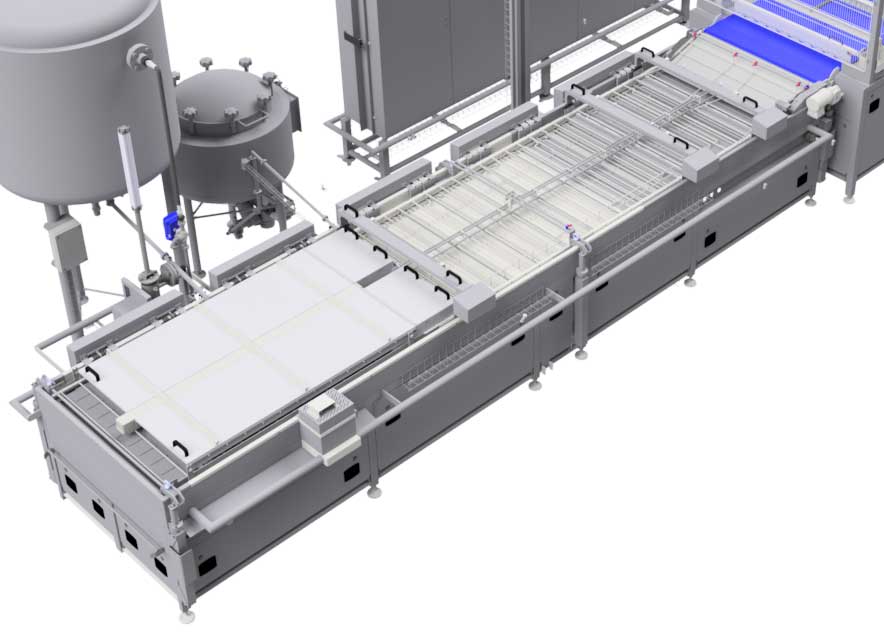

FRYER

- 3 servomotor controlled twists, can be individually switched off and recessed in the tray

- Hydraulic lifting unit for transport use and heating, hence tray accessible from all sides

- Separate heating zones, controlled independently of one another for constant temperature and lower grease absorption