| 1.1 | Conveyor belts |

| 1.2 | Motor with coupling for belt drive |

| 2 | Motor lifting unit |

| 3 | Lifting unit for two lifting trucks |

| 4 | Self-supporting frame |

| 5 | Control cabinet with Beckhoff touch panel control - with multi-level operator menu Operator-Master-Service - internet-capable for remote maintenance - can also be controlled via upstream WP Riehle ComJet with central control system - Supply and discharge systems can be integrated |

| 6 | Fixing frame for mounting of the insulation |

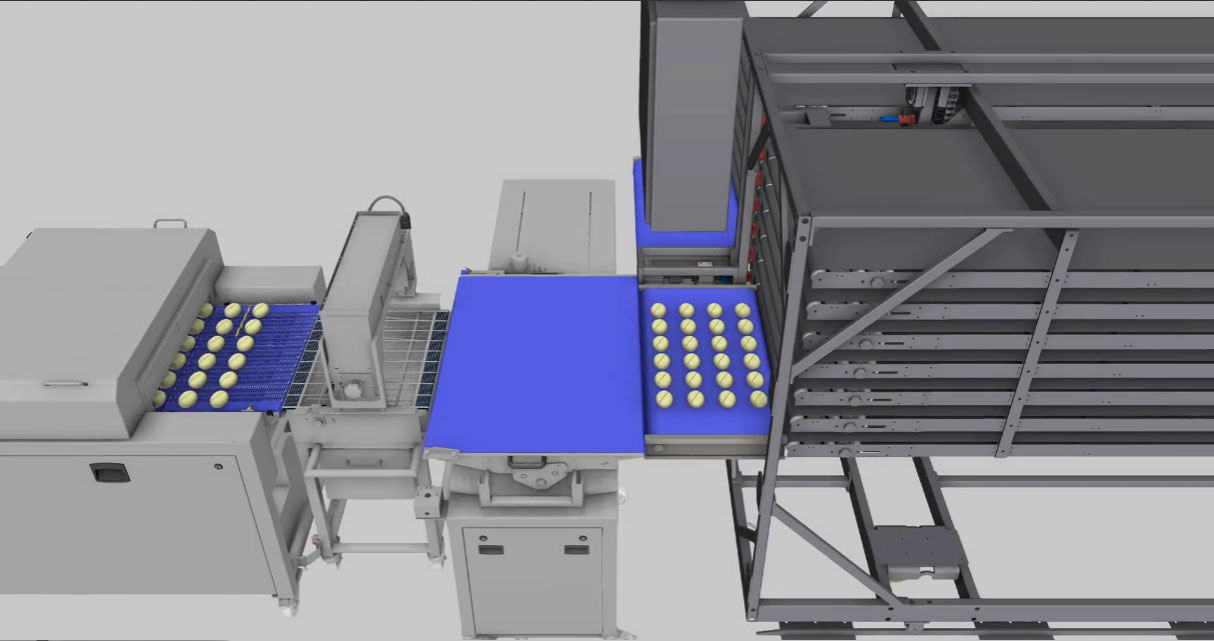

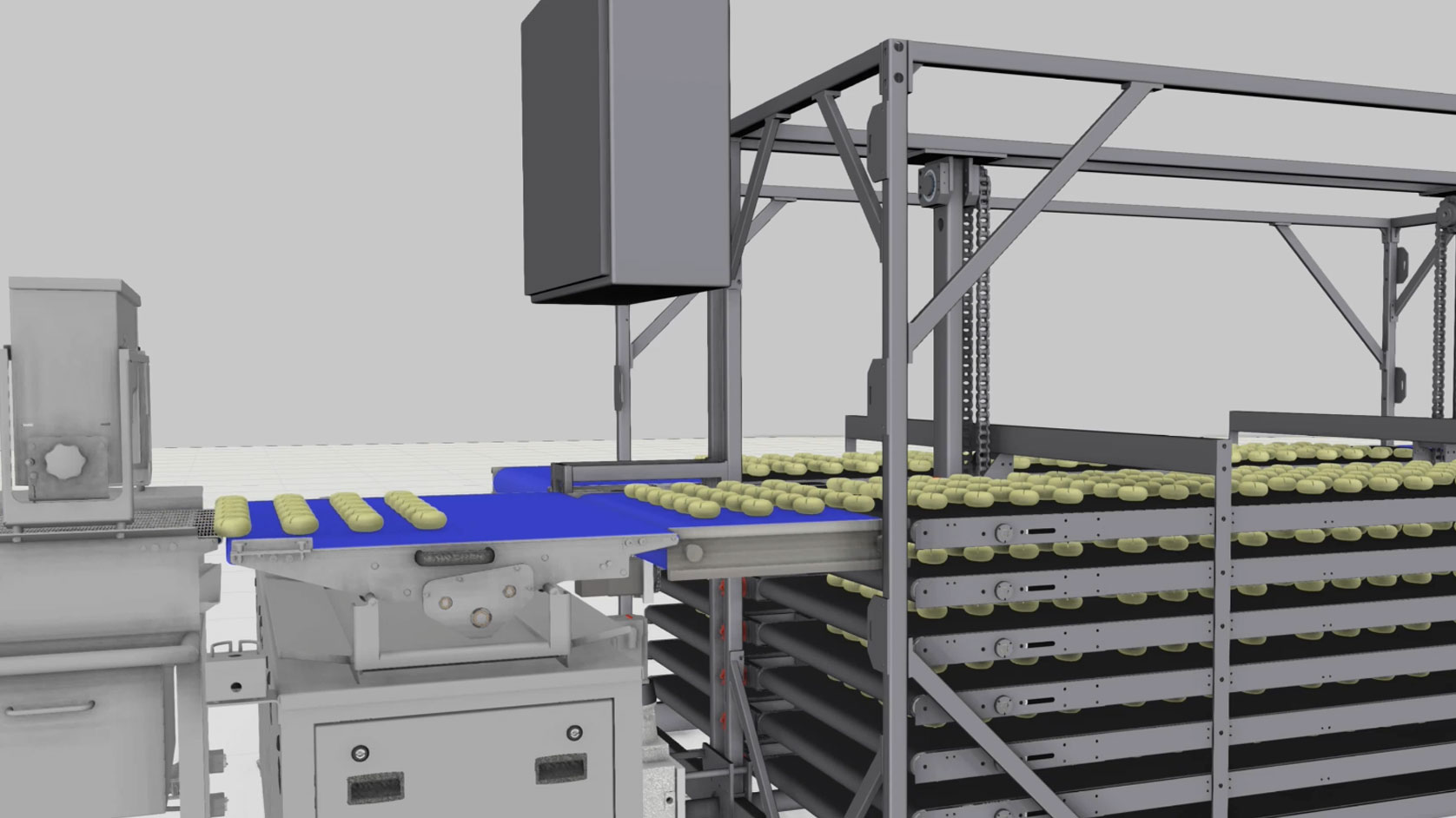

Product input into the Eco-Froster

The products are fed into the freezer via a conveyor belt and transferred to a freezer belt. The outer belt then moves back and the freezer door closes again. This means that only the products themselves (and not the feed systems or trays) need to be frozen.

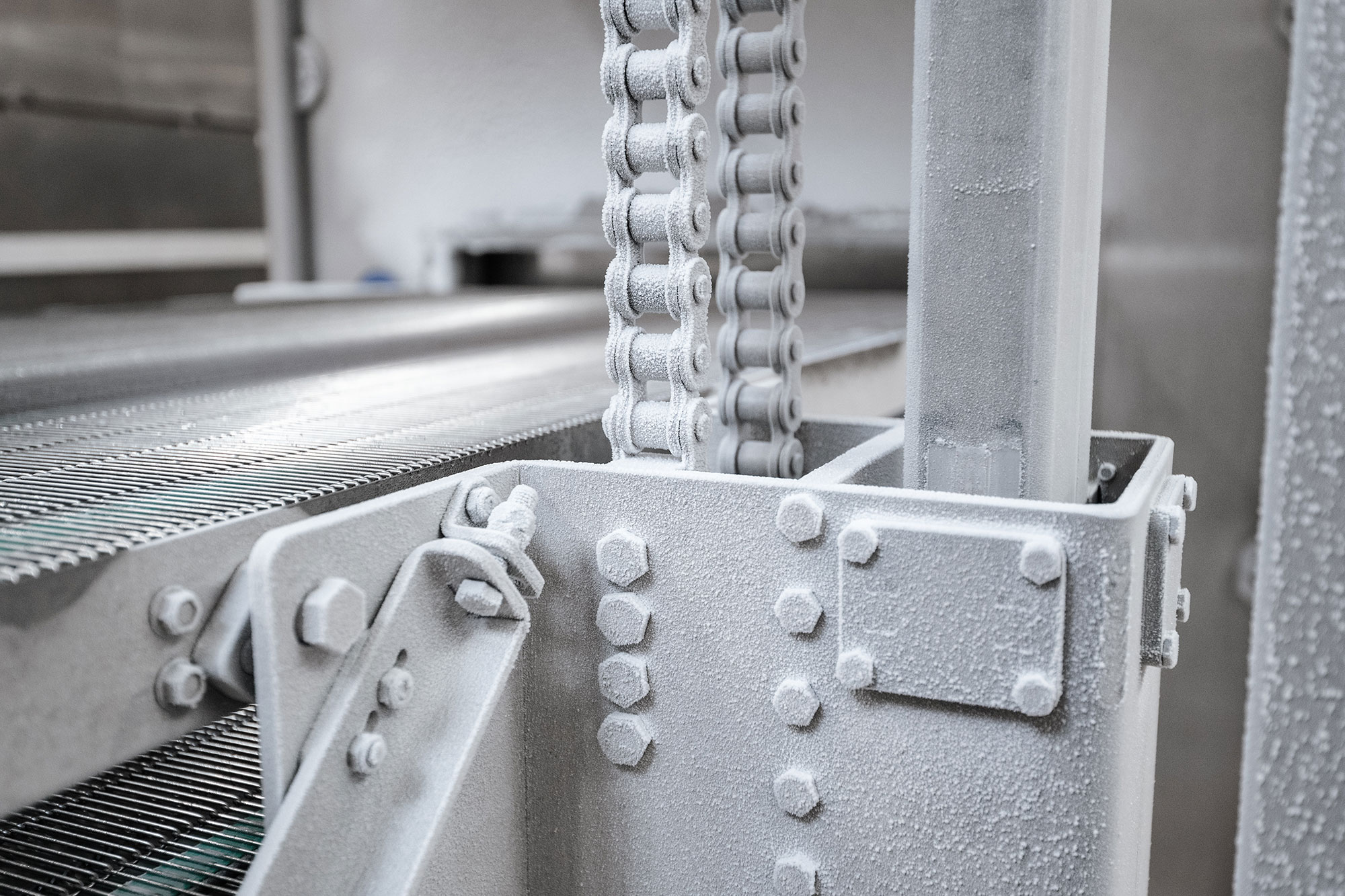

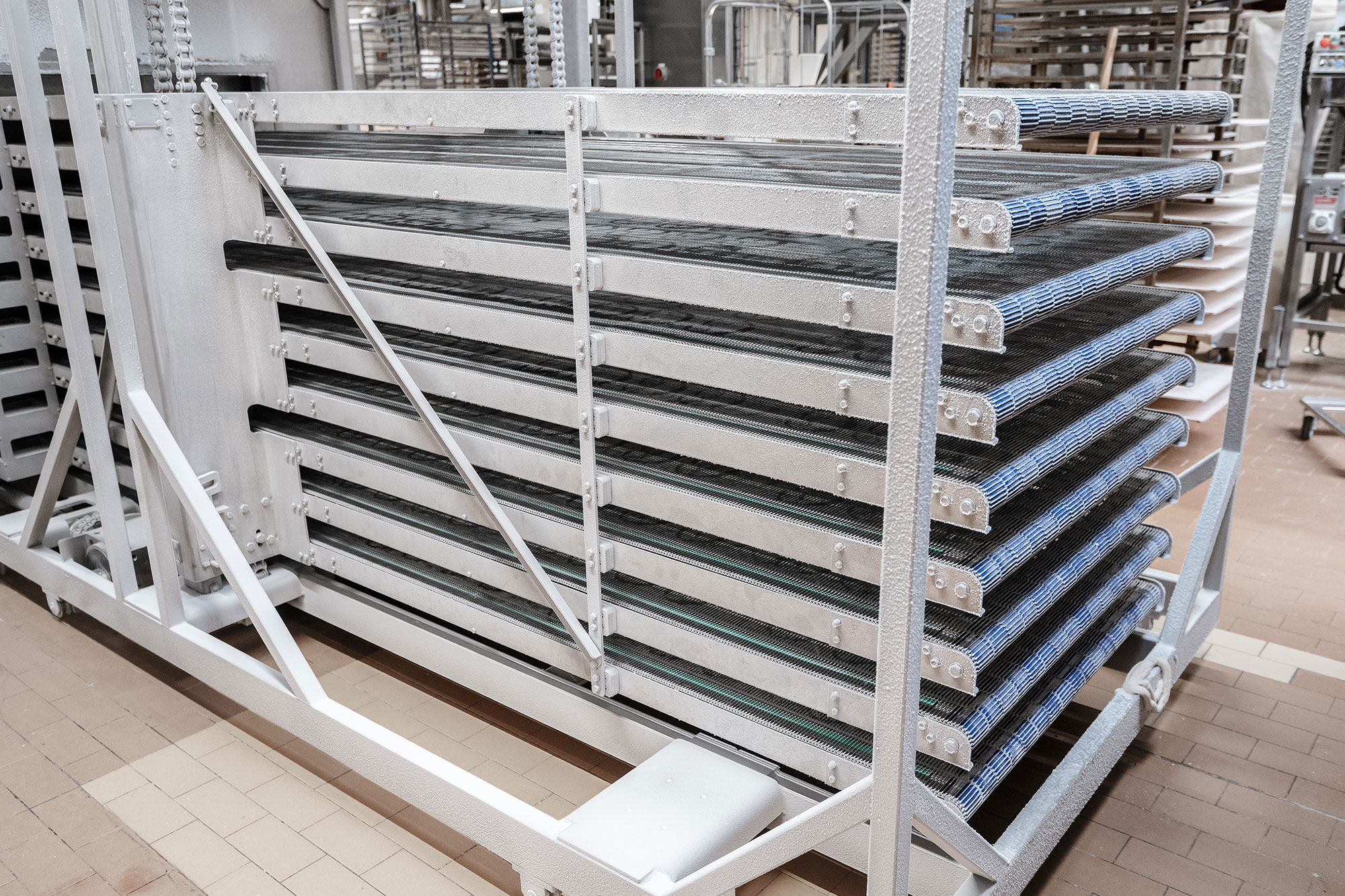

Complete mechanical system in the freezer

The products are detected by a sensor. The flap opens during the loading process and closes again immediately afterwards. The entire mechanism of the paternoster system remains inside the freezer and does not need to be repeatedly cooled during the loading process.

Product output and cleaning

The products are dispensed according to the first-in, first-out principle. Here, they are transported directly into shipping baskets via a metal chute. Connection to other systems would also be possible via a conveyor belt. The WP RIEHLE continuous freezer is therefore ideal for integration into production lines. The entire inner block can be conveniently extended for cleaning the freezer.

Simulation of the Eco-Froster (without case)

Simulation of the Eco-Froster (withour case)

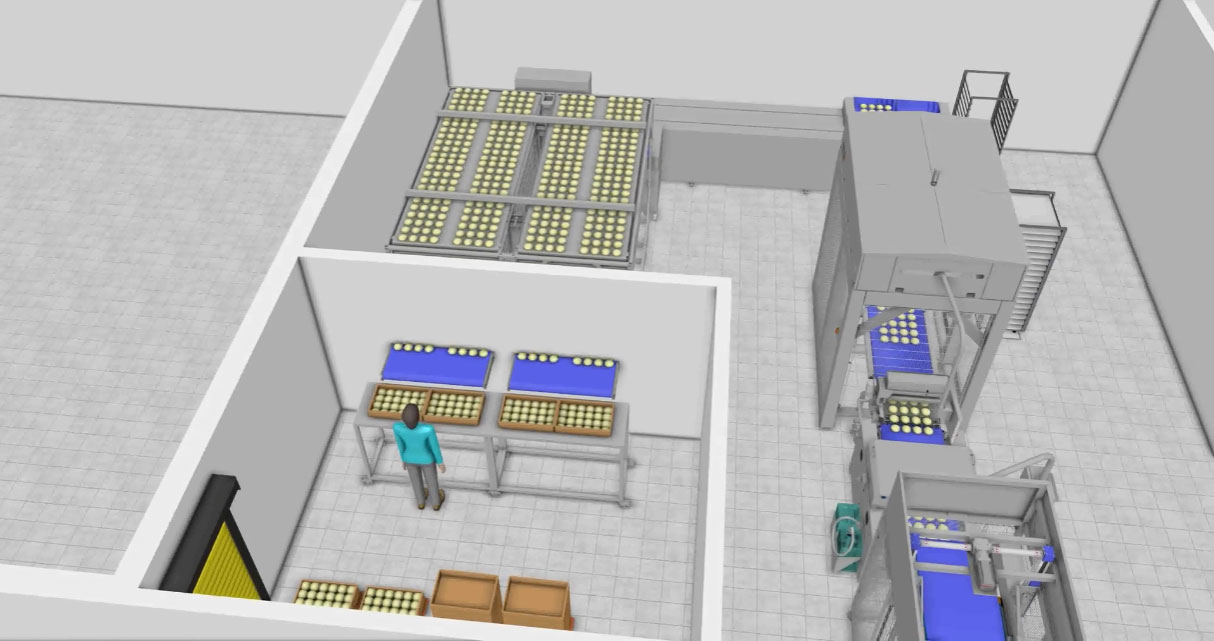

Shock freezing of Pretzels in production line

Simulation of the freezer without housing

| Useful freezing area: | 21-69 m² or larger |

| Dimensions of the frozen products: | hight max. 60 mm, Diameter min. 10 mm |

| Freezing time: | Adjustable settings for processing time |

| Temperature range: | -40°C to +40°C |

| Connections (without cooling): | 16 A/400 V, 6 bar compressed air, W-LAN/network connection for remote maintenance |

![[Translate to Englisch:] Aufbau-Schaubild des Eco-Frosters 4200 [Translate to Englisch:] Aufbau-Schaubild des Eco-Frosters 4200](/fileadmin/_processed_/3/f/csm_schaubild-eco-froster_df6b0d2e74.jpg)