Multi-Clean

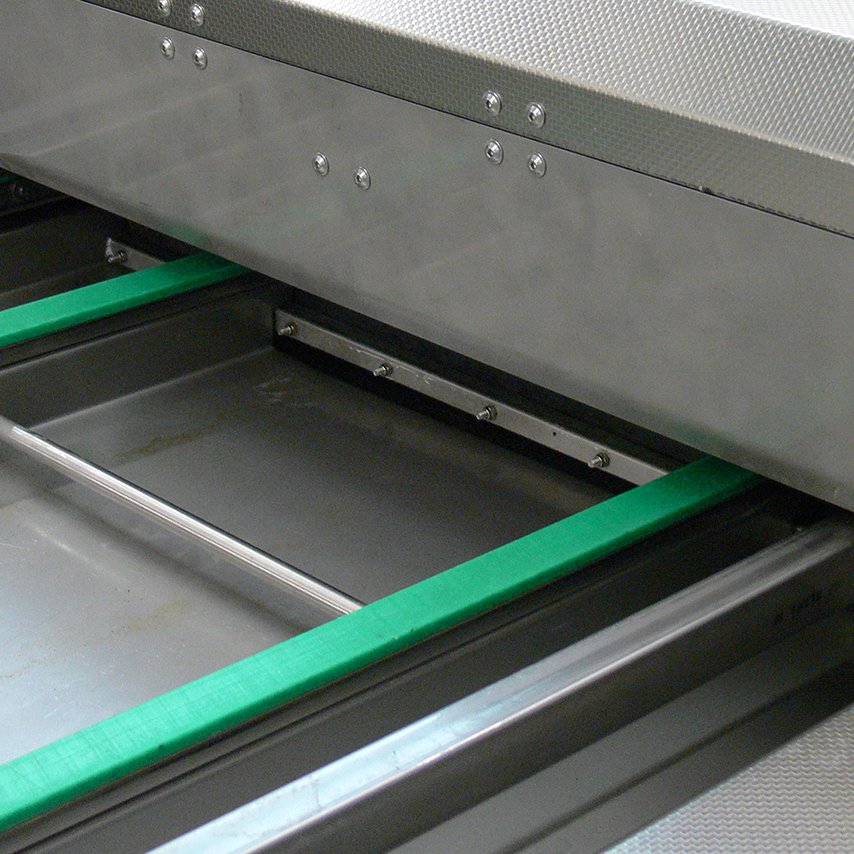

Long service life

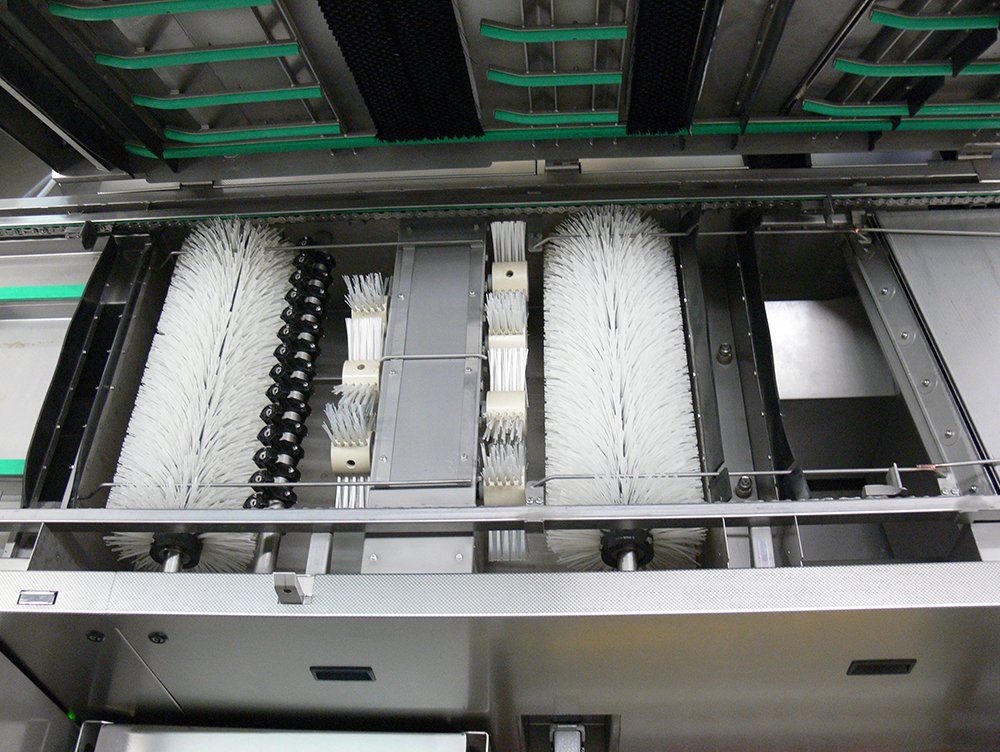

The use of plastic brushes in combination with hot water increases the service life of the sheets and the brushes.

Intuitive touch control

The touch control is resistant to water, dirt and oil. All components are controlled via the user interface, which also allows you to select the various washing programs.

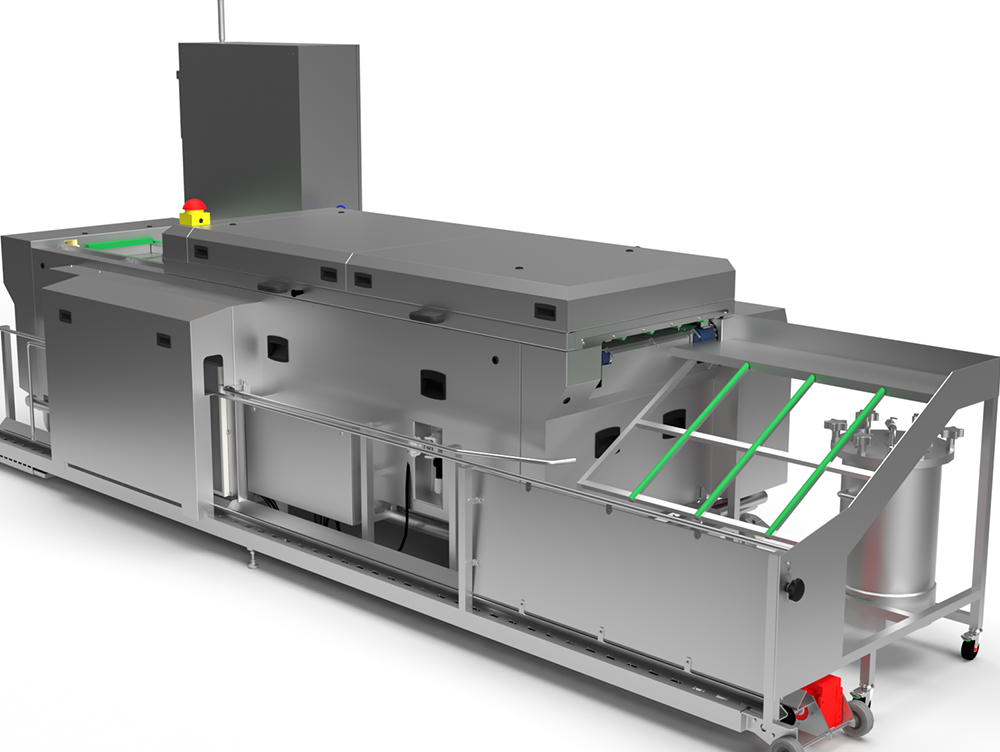

Optional: Lubrication

The recirculation can be enhanced with a lubrication unit. The sheets are lubricated by spraying; the suction unit takes up the excess oil mist. The lubrication unit is equipped with sensors that start and stop lubrication automatically as needed. The corresponding oil quantity and pressure parameters can be configured in the cleaning program.

Air Blades

The sheets are dried by an air blower.

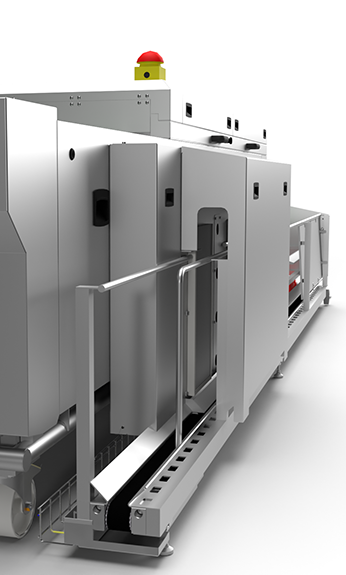

Return conveyor

Due to the return conveyor, the sheet washing machine can be operated by only one person, as the sheets are placed and removed at the same place.

Optional: Lubrication

The recirculation can be enhanced with a lubrication unit. The sheets are lubricated by spraying; the suction unit takes up the excess oil mist. The lubrication unit is equipped with sensors that start and stop lubrication automatically as needed. The corresponding oil quantity and pressure parameters can be configured in the cleaning programme.

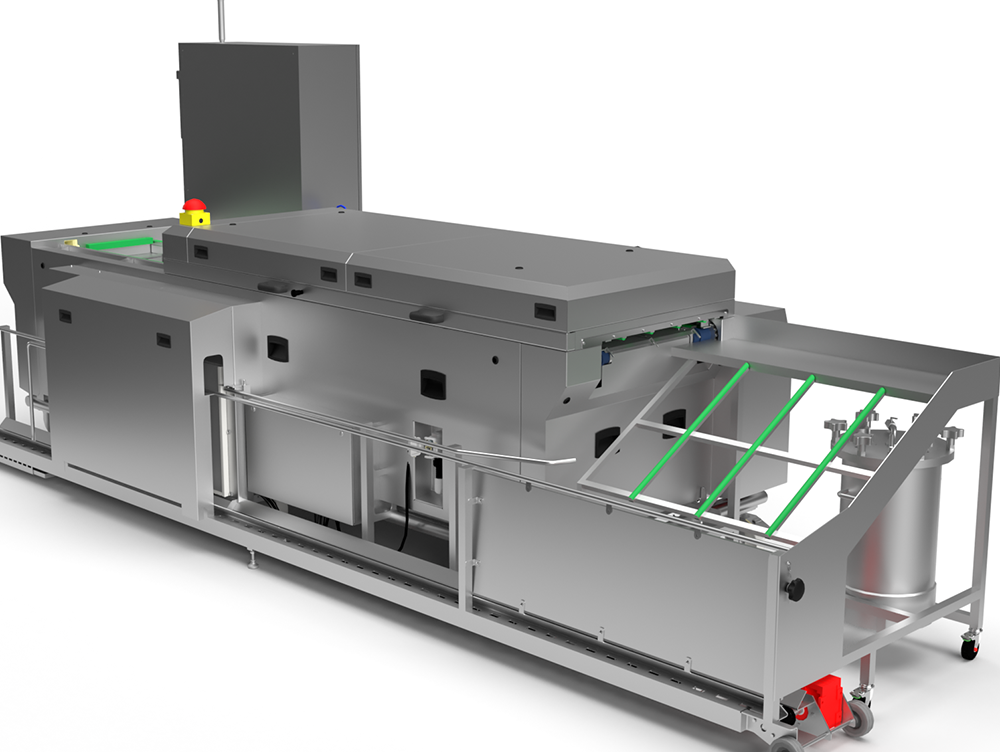

The Multi-Clean wet cleaning system

The MULTI-CLEAN baking tray washing machine raises hygiene standards to a new level. The wet cleaning system ensures optimum operational hygiene with minimum labour and time expenditure. Up to 600 baking trays can be cleaned per hour with just one person.

The BWM Multi-Clean is suitable for manual to industrial production. The tray washing machine is adjustable from light and quick cleaning to cleaning the heaviest soiling. Various washing programmes, temperature settings, container feed and brush speed modes make it suitable for a wide range of applications. Defined washing programmes enable compliance with IFS and HACCP standards for process safety. The machine is manufactured in accordance with the latest European safety guidelines. The defined washing programmes ensure compliance with IFS and HACCP requirements.

Conservation of resources is a top priority

The baking trays are carefully treated using plastic brushes, detergent and hot water. Your employees benefit from an efficient working method with short distances and ergonomic operation. The operator also has no direct contact with cleaning agents. The Multi-Clean is also impressive when it comes to environmental protection: the automatic dosing of water and washing-up liquid means that resources can be conserved. Water consumption, waste water and detergent consumption are significantly minimised.

Baking tray cleaning using the wet cleaning method

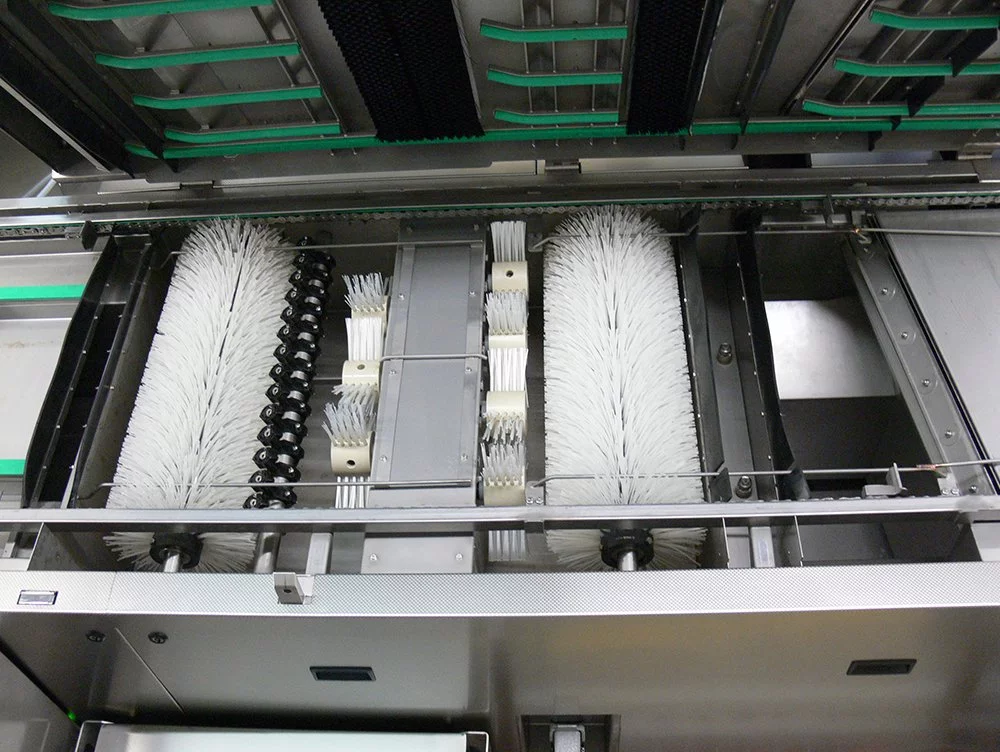

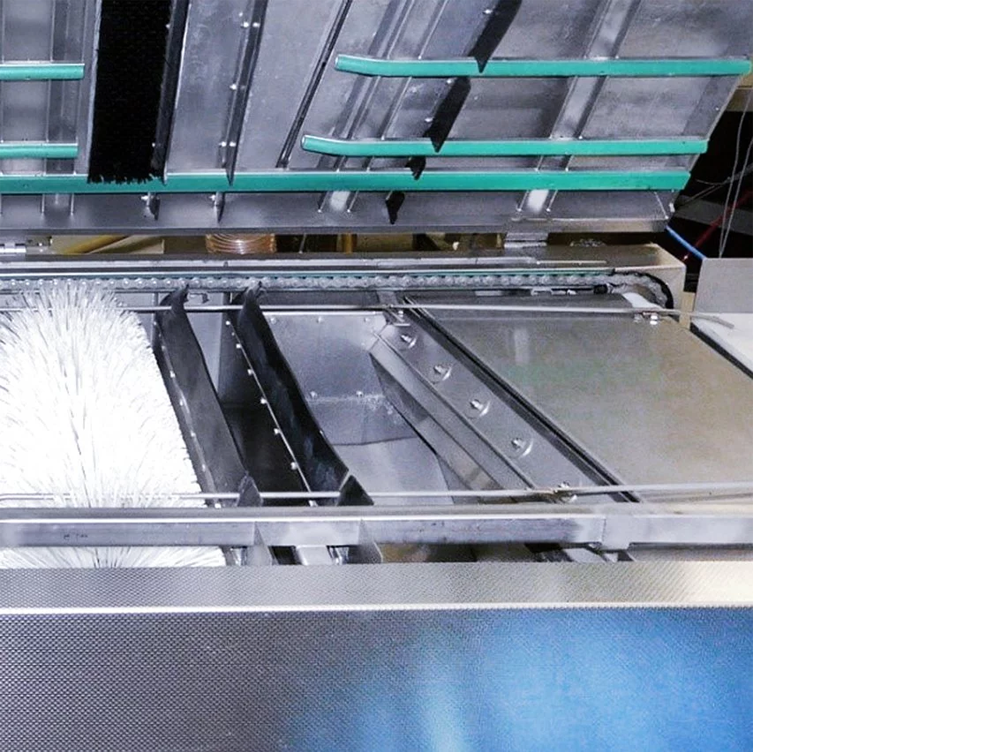

The Multi-Clean can be fed with all standard-sized trays, from rimless to square trays with an edge height of up to 25 mm. It has a tray support with a tray detection sensor: the conveyor belt is equipped with carriers for the trays, the tray sensor recognises when a tray has been placed and automatically starts the conveyor belt. Multi-zone brush cleaning takes place in the system: Zone1: Pre-cleaning of the baking trays with a rotating surface brush, Zone 2: Pre-cleaning of the edges with rotating edge cleaning brushes, Zone 3: Final cleaning of the edges with rotating surface brushes, Zone 4: Final cleaning of the baking surfaces, all 4 zones each with hot water and automatic detergent dosing. Zone 5 is followed by rinsing. This is followed by tray drying with professional air blades.

As an option, the trays can be automatically returned to the operator via a return conveyor to the loading point. This allows loading and unloading at the same place. An oiling unit is also available as an option. It is automatically switched on and off by a sensor as the trays pass through. Oil is automatically applied to the baking side of the baking trays via spray lubrication, the excess oil is then removed by a filter. The oil quantity and pressure parameters are stored in the cleaning programme.

Connecting the machine

The machine is connected directly to the cold or hot water supply. It has an automatic, sensor-controlled dosing system for water and detergent. An instantaneous water heater provides clean rinsing water. In addition to a fresh water supply, an electrical connection, a waste water connection, compressed air, detergent and liquid oil for the optional oiling unit are required for the connection.

Control of the system

The touch control enables intuitive user guidance. It is insensitive to water, dirt and oil. Several user levels allow different access rights. Various washing programmes and oiling parameters can be stored here. Temperatures, tray feed speed and brush speed are set and monitored via the control unit, which also logs and monitors errors. The control unit is internet and remote maintenance capable. The instructions on the touch control panel can be translated into the local user language when ordering.