Lye application

DBA

- Ideal for production lines

- Top quality with high throughput

- Closed lye circulation

Modular lye application machine DBA

the all-round talent for line production

The modular lye application machine is the ideal solution for integrated use in automated production lines.

Optionally: Automatic lye management

The DBA with optional PRO equipment: In addition to a lye level sensor, the (extendable) lye tank also features automatic lye tank refilling, which draws lye from a lye canister when the lye level is low and draws water via a permanent water supply (with a mains isolator to prevent backflow into the drinking water system).

The lye concentration is mixed automatically. A measuring device in the tank monitors the lye concentration for perfect and consistent lye application results.

A lye tank heating also ensures the optimum lye temperature to guarantee clean lye application with the best baking results.

With the PRO equipment, you are choosing a solution that makes your production processes significantly more efficient while also meeting the highest safety standards. Thanks to sophisticated technology and optimised processes, not only is productivity increased, but handling lye also becomes much safer. This allows you to consistently reduce risks and create a working environment that protects, relieves stress and builds trust.

Maximum performance – for your high-volume automation

The actual lye application capacity depends on the upstream and downstream systems. The cycle time is programmable and depends on the speed of the entire line.

- Optional passage widths in the lye application machine:

- 660 mm

- 1,000 mm

- Individual widths on request

- Lye application process:

- Programmable timing for consistently high quality even at maximum throughput

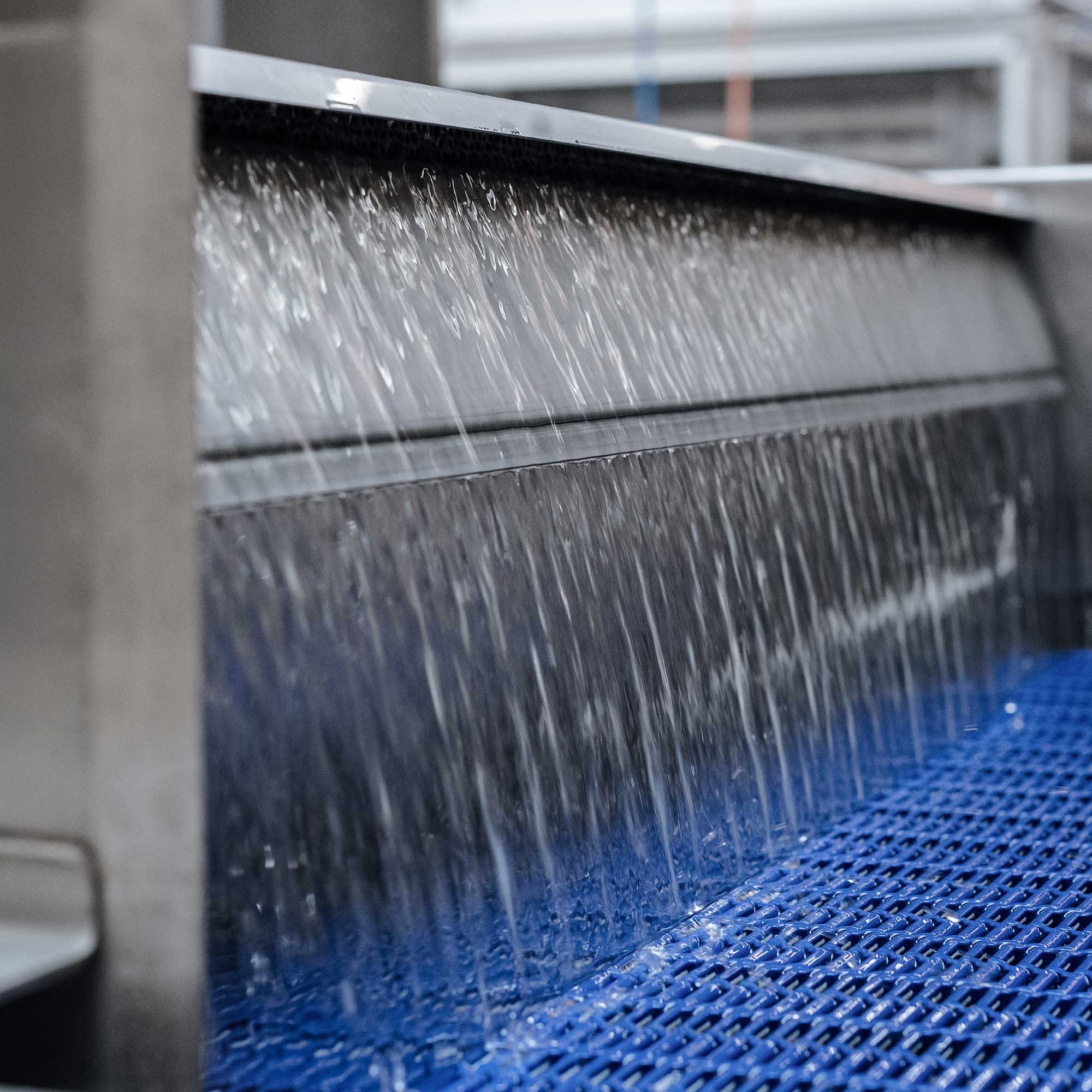

- Patented lye shower and double lye curtain for optimum lye distribution at high throughput speeds

- Operation:

- The lye level sensor provides early warning if the lye level in the tank is too low

- Extendable lye tank with fill level sensor and active measurement of lye concentration

- Viewing window for easy checking of the lye level

- Lye tank heating for constant lye temperature and even lye distribution

- Control and remote maintenance

- Internet and remote maintenance capable

- Touch panel:

- Resistant to water, dirt and oil

- Controls can be set to country-specific language

- Intuitive operation, different user levels with individual access rights

- Various programmes and belt speeds can be selected

- With real-time monitoring, logging and automatic error monitoring, production statistics, utilisation and efficiency data

- Separately switchable component control

- Cleaning

- Quick and easy

- The machine can be easily moved for cleaning thanks to the attached castors

- Sieves and containers for collecting deposits and residual liquids

Performance

Output depends on the upstream machine.

Options

- Higher lye application device for baked goods taller than 100 mm

- Sprinkling device with integrated brush roller

- Loader (WP Automatic Loader)

- Various spring belt variants

For all types of pretzel pastries

Please consider your specific requirements when choosing the lye

Pretzel

Pretzel

Croissant

Pretzel sticks

Laugenstange

Laugenkonfekt

Lye rolls

Modular Lye application machine as part of a Comjet (with loader) and freezer connection

Our sales staff will be happy to answer any questions you may have about the product.