BRM

Solid design

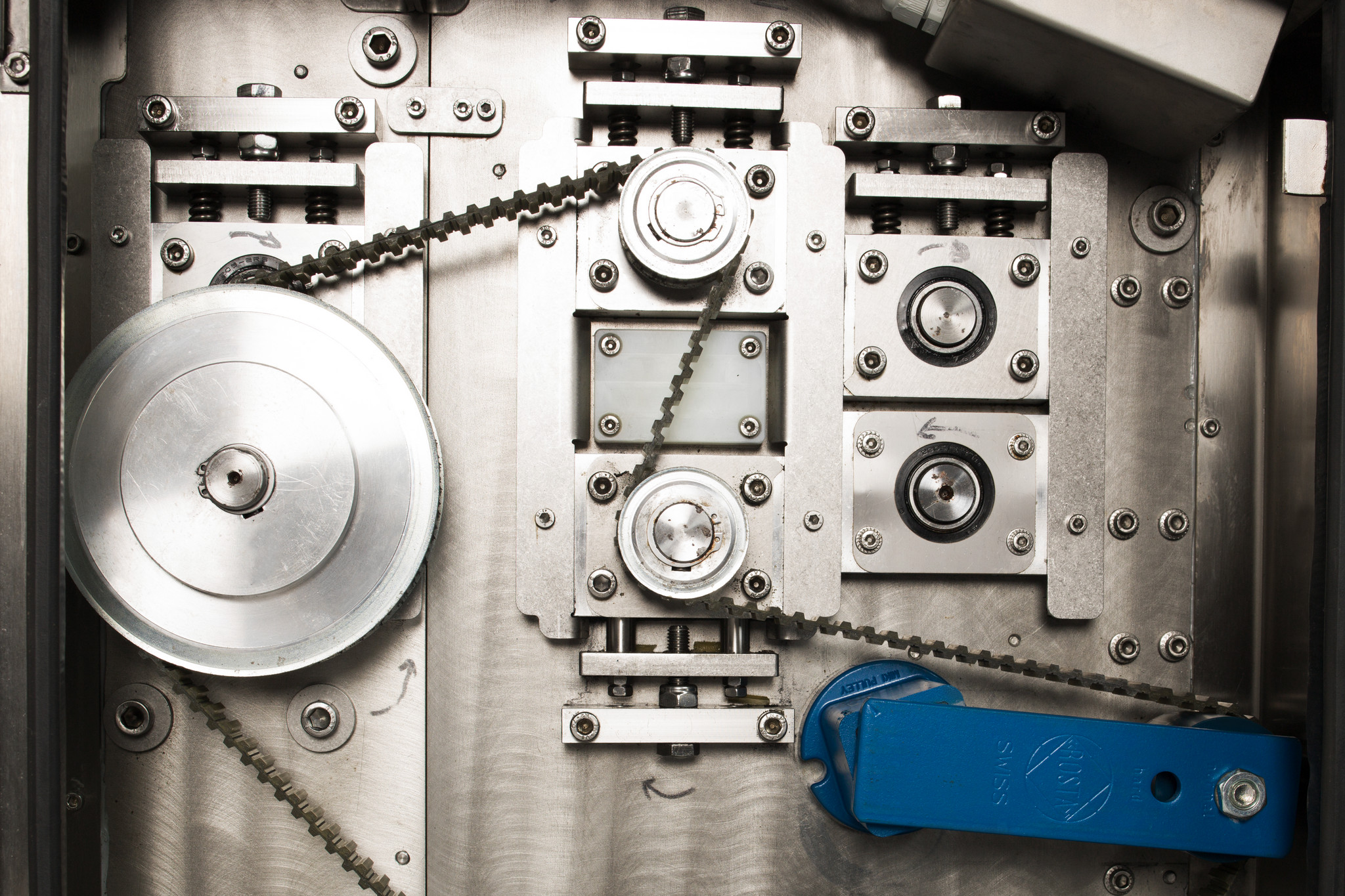

The solid and robust structure of the BRM DELUXE is designed for durability and high throughput. The 6 mm thick side walls ensure exact parallelism, even on uneven bakery floors.

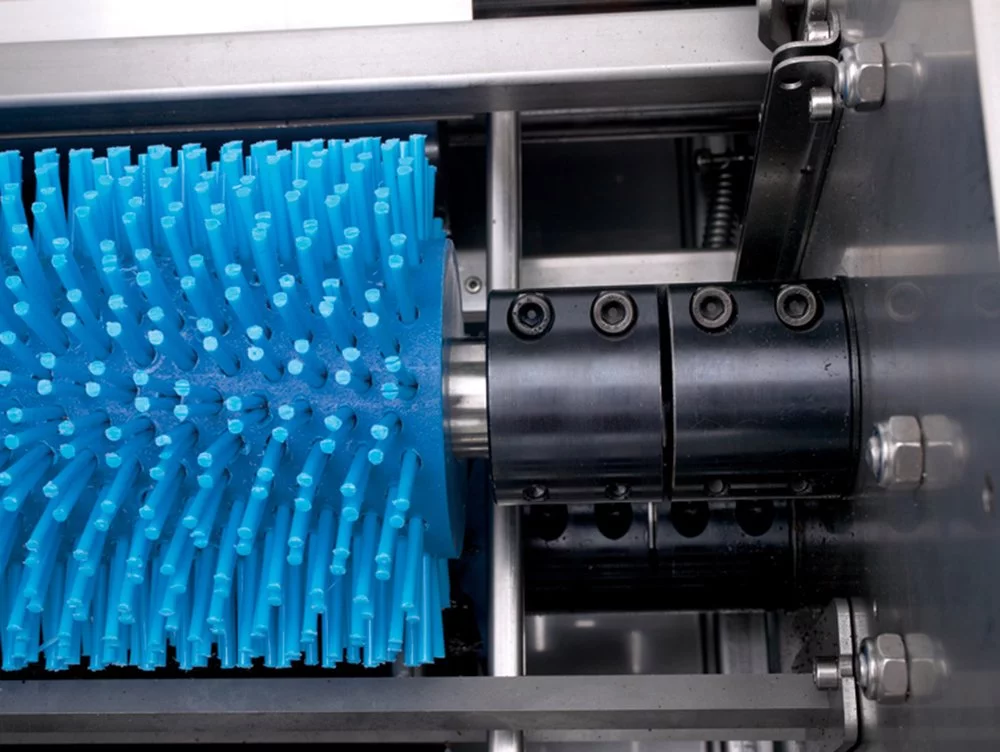

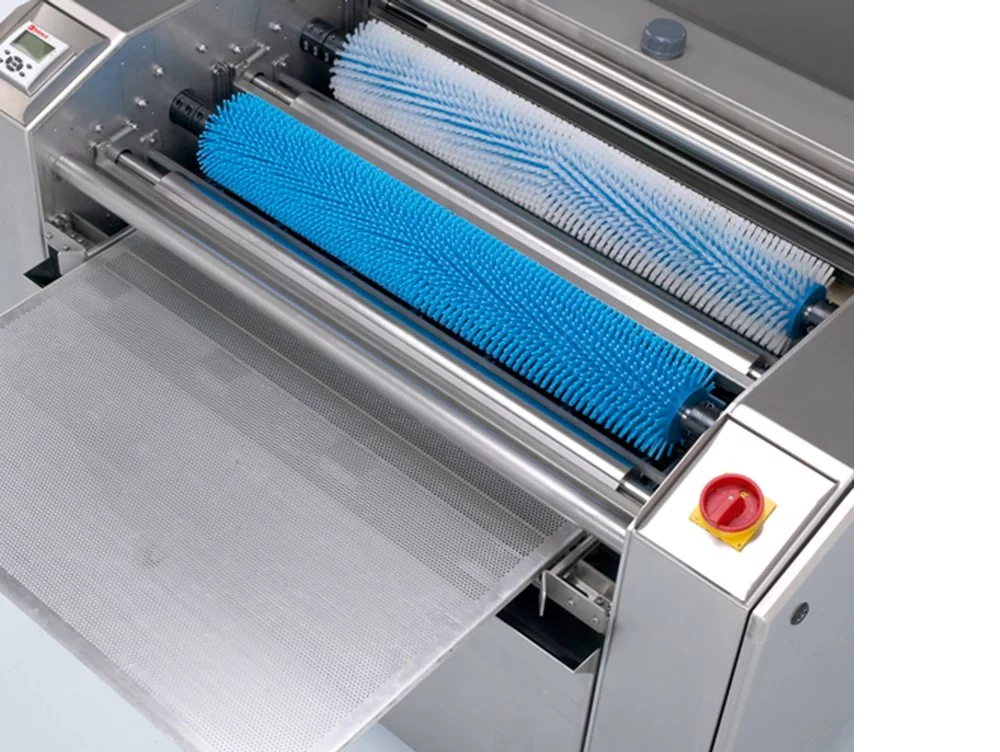

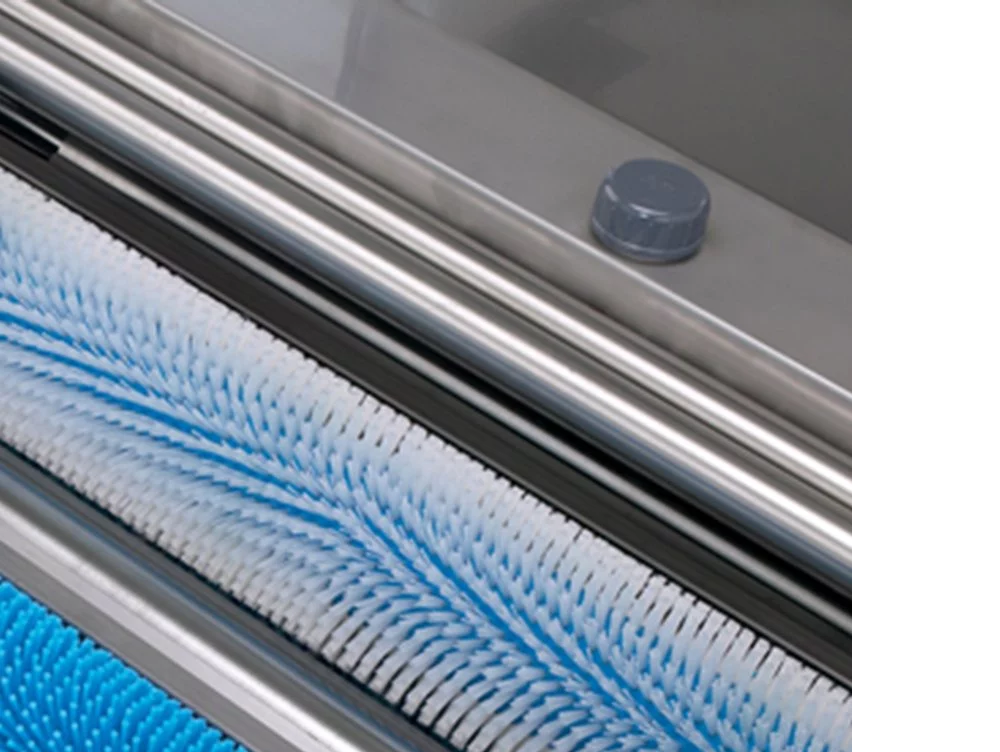

Optimum cleaning

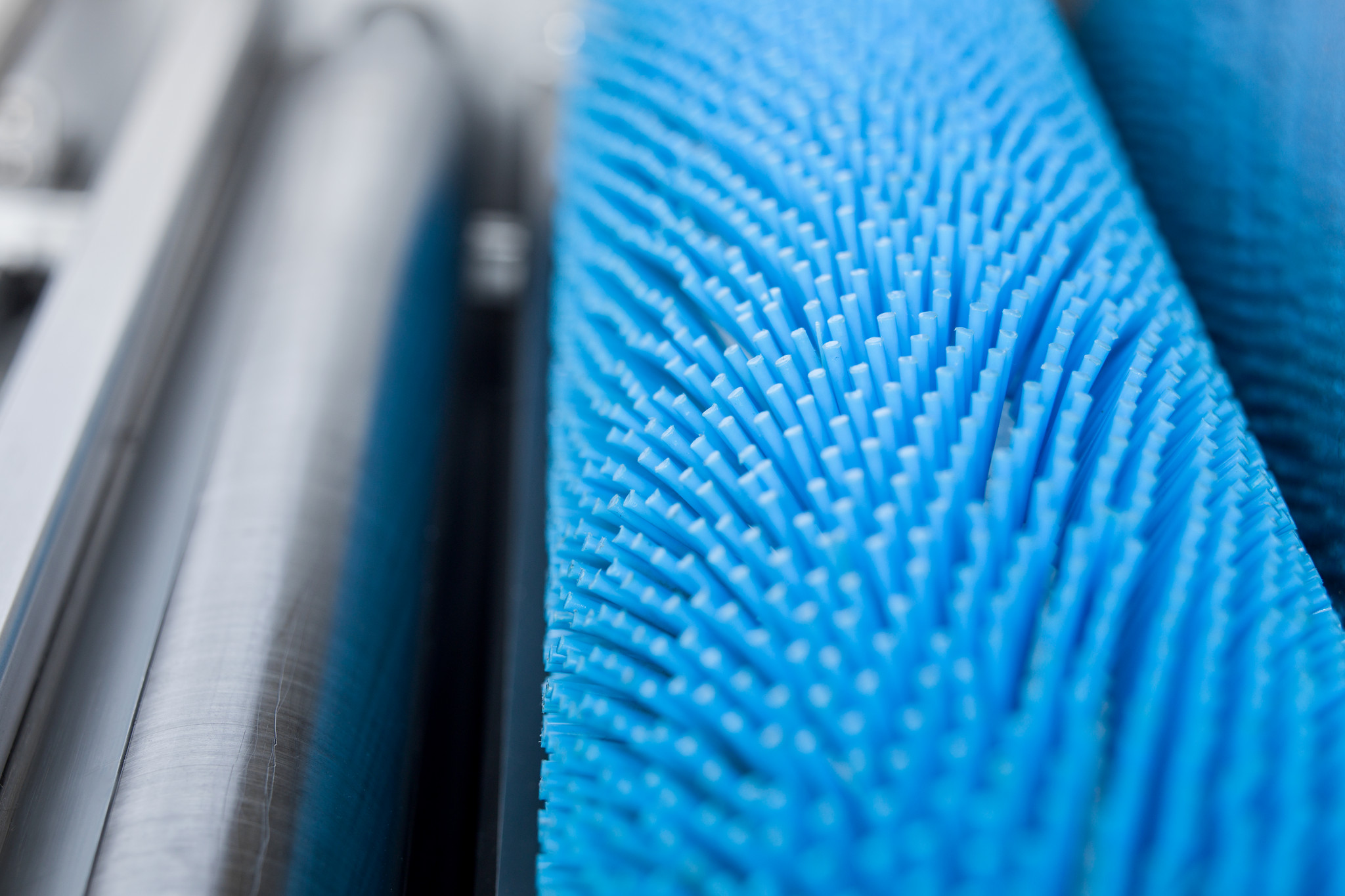

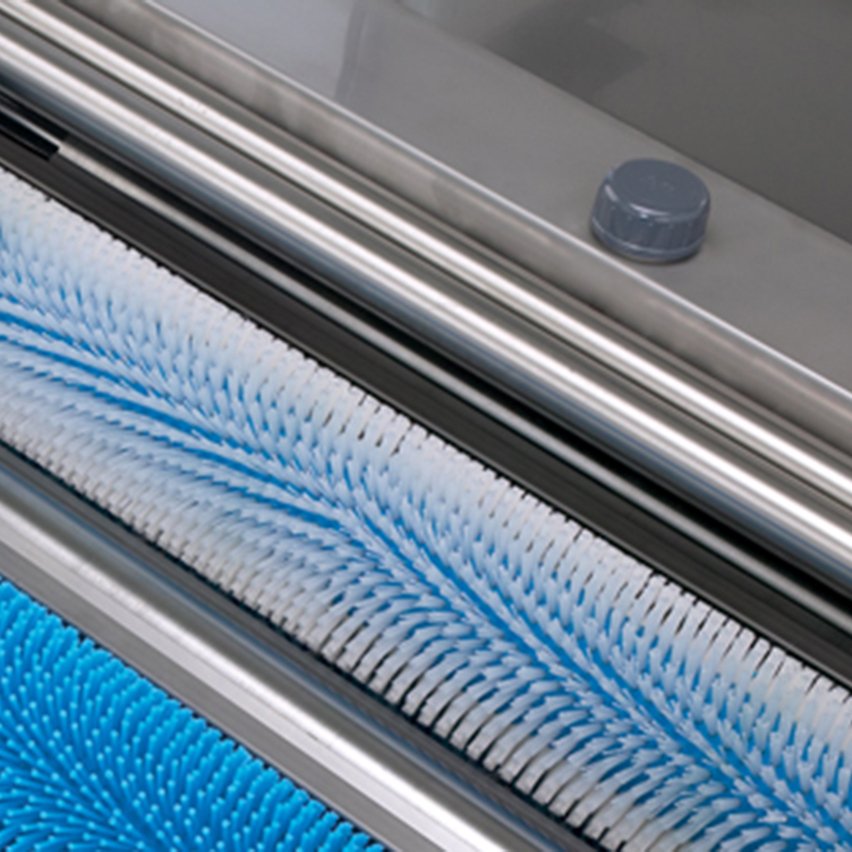

The sheet is fed into the infeed with the lower baking side, where it is gripped by feed rollers and transported via four rotating, height-adjustable brushes that clean the sheet on both sides.

Gentle on the sheet

The spring-mounted and readjustable brushes prevent rolling and bending of the sheets.

Optional: Lubrication

The BRM DELUXE is also available with automatic lubrication and an integrated storage tank.

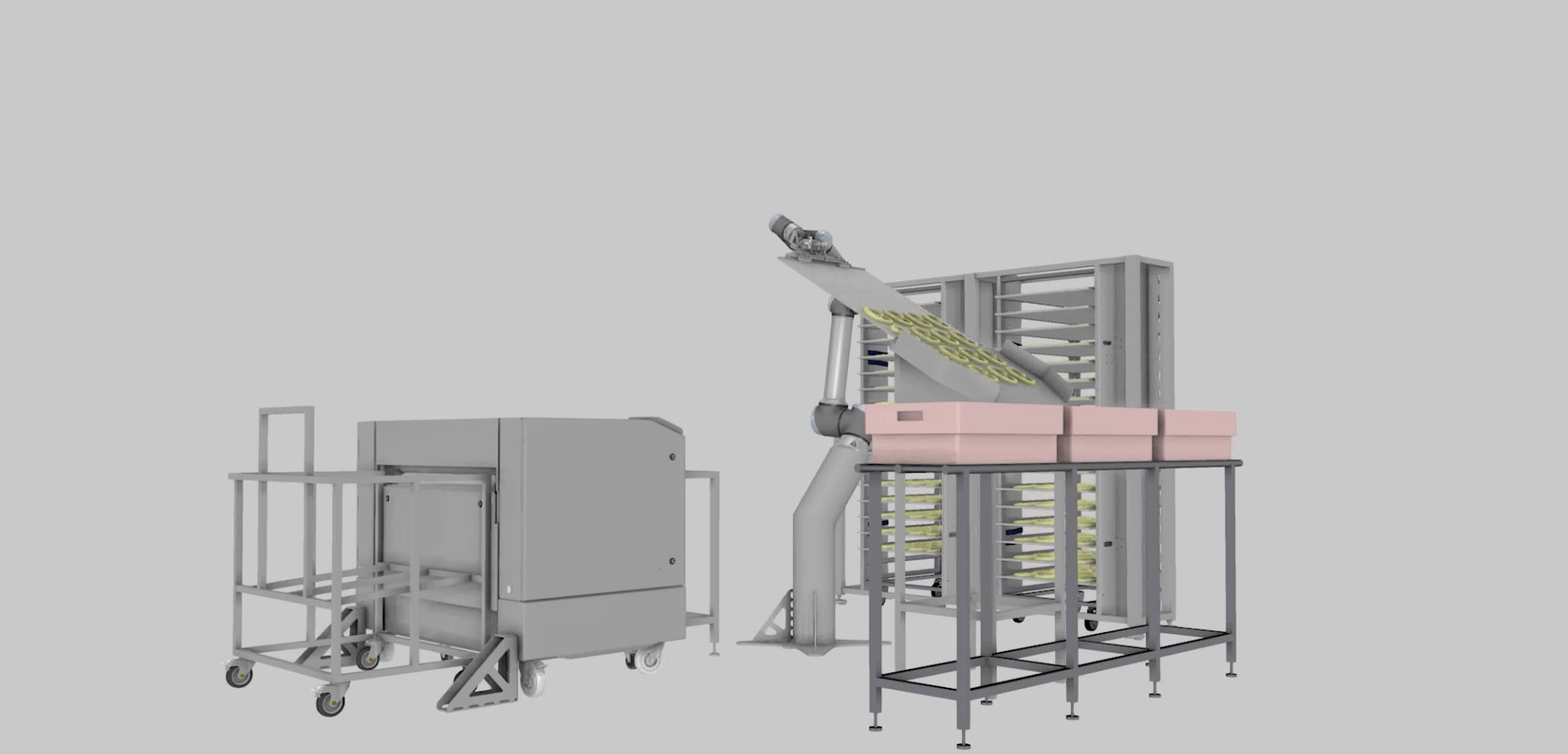

BRM DELUXE dry cleaning system

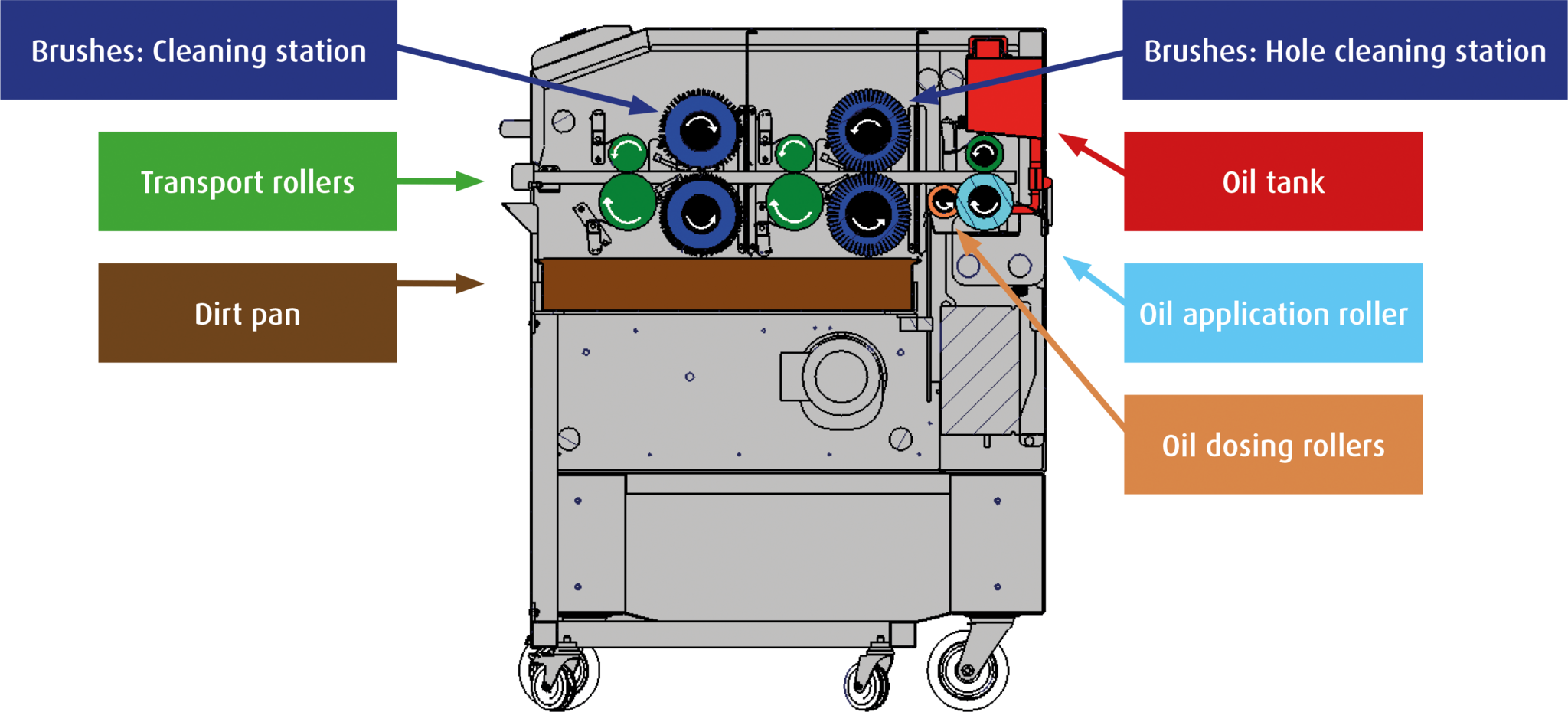

The BRM Deluxe dry cleaning system enables baking trays to be cleaned and oiled in just one work step. It works quickly, effectively and hygienically. It cleans all standard double-sided baking trays and perforated trays. You can clean and grease up to 700 trays per hour with just one person.

Cleaning the baking trays

Various cleaning programmes can be stored in advance via the computer control system. The tray is then fed into the infeed with the baking side facing downwards, where it is gripped by infeed rollers and transported over two rotating, height-adjustable brushes that clean both sides of the tray. Two cleaning stations ensure the best cleaning results. The separate hole cleaning station gives your baking trays clean holes. The spring-loaded and height-adjustable rollers prevent trays from being rolled out. Oiling is then carried out automatically and economically. The optional trolley for removing the cleaned trays is also very useful.

Cleaning the system

The BRM Deluxe has a convenient cover opening for maintenance and cleaning. The quick-release coupling on all brushes makes it easy to remove the brushes without having to readjust the spacing when reinserting them. The extendable dirt pan also makes cleaning the system extremely easy.

Quick and hygienic cleaning of all double-edged baking and perforated trays